- #1

Cobrasvt1999

Hello all and thanks in advance for the help!

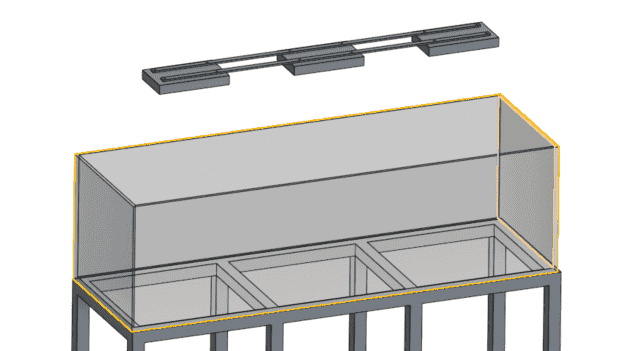

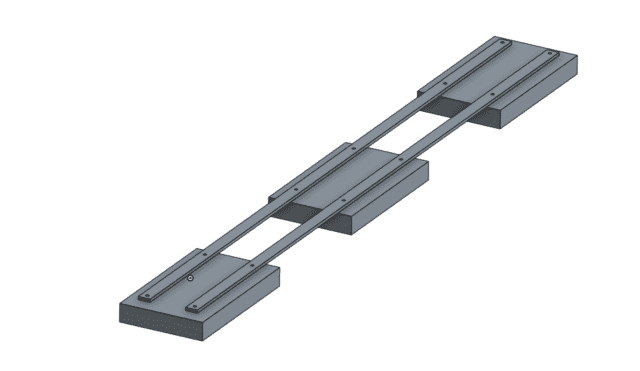

I am currently working on creating a lighting fixture that will be suspended over an aquarium. What I am having trouble with is determining a safe material and thickness for the spars going between the lights (see below). My goal is to have these spars be as low profile as possible yet still safe and reliable for long term. Because of the low profile needs I would prefer to use some type of flat stock rather than angle stock or square stock. MY current thought is to use aluminum bar stock as it is easy to get and reasonably priced, but I am unsure of the strength. Anyone have any suggestions on materials? How would I figure out the loading on the spars?

Each light fixture weights aprox 5 lbs

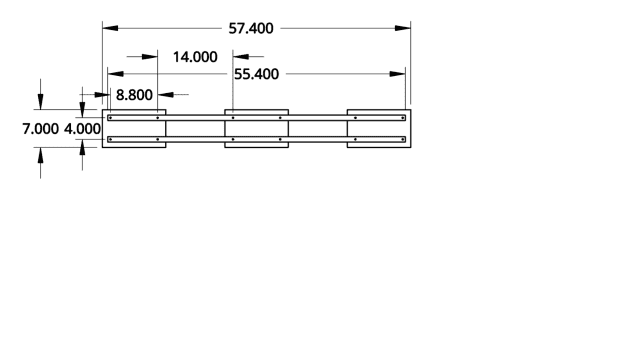

all dimensions are in inches

assume no Flex in fixtures and each fixture has 4 mounting points

Spars need to be at least 3/4 inch wide for mounting points.

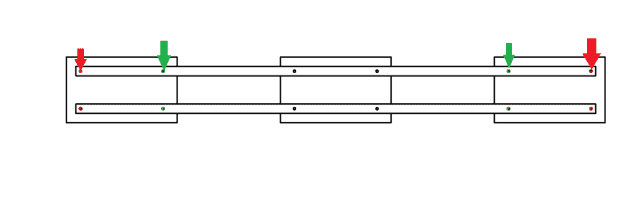

Fixture will be hung from 2 cables on either side (see attaching points below)

As for hanging locations, I would prefer to hang the fixture from the red points for aesthetic reasons, however I assume that the green mounting points would provide a decent counterbalance to the suspended light in the center. Thoughts?

Once again, I really appreciate any help that can be provided with this. these are extremely expensive lights so I really want to be sure that it will hold for the long term!

I am currently working on creating a lighting fixture that will be suspended over an aquarium. What I am having trouble with is determining a safe material and thickness for the spars going between the lights (see below). My goal is to have these spars be as low profile as possible yet still safe and reliable for long term. Because of the low profile needs I would prefer to use some type of flat stock rather than angle stock or square stock. MY current thought is to use aluminum bar stock as it is easy to get and reasonably priced, but I am unsure of the strength. Anyone have any suggestions on materials? How would I figure out the loading on the spars?

Each light fixture weights aprox 5 lbs

all dimensions are in inches

assume no Flex in fixtures and each fixture has 4 mounting points

Spars need to be at least 3/4 inch wide for mounting points.

Fixture will be hung from 2 cables on either side (see attaching points below)

As for hanging locations, I would prefer to hang the fixture from the red points for aesthetic reasons, however I assume that the green mounting points would provide a decent counterbalance to the suspended light in the center. Thoughts?

Once again, I really appreciate any help that can be provided with this. these are extremely expensive lights so I really want to be sure that it will hold for the long term!