- #1

duhuhu

- 59

- 2

Hey guys!

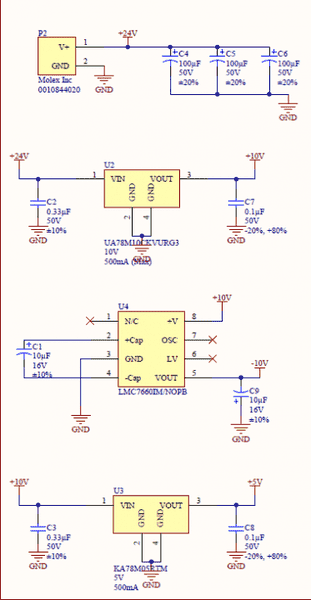

I have been having a lot of problems with a board I am working on. The board was originally designed for 24 volts, but my input is 28 (non negotiable), so to make things easier than redesigning the whole power circuit, I am just doing a step down to 24 right when it goes into my box. The problem that I am having is that when I hook up the whole circuit with 28, It blows my 24->10 volt regulator. But when I run the original circuit on 24, it works just fine. I have checked the entire rest of the board and there are no shorts. This board was given to me by the last guy to work on the project (who now cannot help me due to conflicts of interest), and it does not have a top coat, so there are exposed wires, but they don't seem to be causing any noticeable issues...

Unfortunately I don't have the specs on the 28->24 volt regulator. It is just a little black box circuit that my professor gave me. But I can say that it draws 10mA by itself (which seems right to me).

the attached image is the power circuit (excluding the black box regulator), the second chip (U2) is the one that keeps blowing out.

Do you guys have any ideas for what I could do to help keep this issue from happening?

I am not a wizard with electronics, in fact this is my first big project, It may be something stupid that I am doing, so if I say something that sounds really stupid to you guys, please just bear with me.

Thanks!

I have been having a lot of problems with a board I am working on. The board was originally designed for 24 volts, but my input is 28 (non negotiable), so to make things easier than redesigning the whole power circuit, I am just doing a step down to 24 right when it goes into my box. The problem that I am having is that when I hook up the whole circuit with 28, It blows my 24->10 volt regulator. But when I run the original circuit on 24, it works just fine. I have checked the entire rest of the board and there are no shorts. This board was given to me by the last guy to work on the project (who now cannot help me due to conflicts of interest), and it does not have a top coat, so there are exposed wires, but they don't seem to be causing any noticeable issues...

Unfortunately I don't have the specs on the 28->24 volt regulator. It is just a little black box circuit that my professor gave me. But I can say that it draws 10mA by itself (which seems right to me).

the attached image is the power circuit (excluding the black box regulator), the second chip (U2) is the one that keeps blowing out.

Do you guys have any ideas for what I could do to help keep this issue from happening?

I am not a wizard with electronics, in fact this is my first big project, It may be something stupid that I am doing, so if I say something that sounds really stupid to you guys, please just bear with me.

Thanks!