- #1

DaveC426913

Gold Member

- 22,947

- 6,632

I'm building a widget that requires tetrahedral arrangement of universal joints.

Currently, I'm only concerning myself with half of the u-joint - the half attached at the tetrahedron. (essentially just the one bar)

I want the arrangement of the U-joints to be as symmetrical as possible around the tetrahedron. i.e. you should be able to rotate the 'tet' about any of its axes and end up with the exact same configuration, or if you rolled it like a die, you could not tell which of the four faces were up, since they're identical.

This is not actually possible.

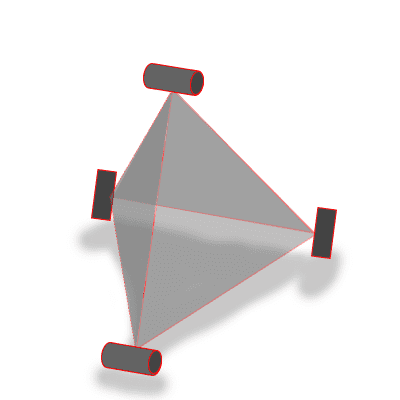

Here is a tetrahedron with four bars attached:

I can rotate the 'tet' but I will not always get the same orientation of bars. It is sitting on one horizontal bar at the front and two vertical bars at the rear. If I were to rotate the tet 120 degrees, it would have a vertical bar at the front, thus I would be able to tell which face is toward me. It has a bias.

While I can't have true symmetry, I wonder if it is possible to least attain some rotational symmetry. That would give the tet a chiral bias, (clockwise would not be the same as CCW) but at least it would have some symmetry.

I'm not sure how to work this out, or, if it can't be done, why not. What am I encountering here that a highly symmetric object (a tetrahedron, or simply four point on a sphere) is broken by the addition of a bar at each vertex?

Currently, I'm only concerning myself with half of the u-joint - the half attached at the tetrahedron. (essentially just the one bar)

I want the arrangement of the U-joints to be as symmetrical as possible around the tetrahedron. i.e. you should be able to rotate the 'tet' about any of its axes and end up with the exact same configuration, or if you rolled it like a die, you could not tell which of the four faces were up, since they're identical.

This is not actually possible.

Here is a tetrahedron with four bars attached:

I can rotate the 'tet' but I will not always get the same orientation of bars. It is sitting on one horizontal bar at the front and two vertical bars at the rear. If I were to rotate the tet 120 degrees, it would have a vertical bar at the front, thus I would be able to tell which face is toward me. It has a bias.

While I can't have true symmetry, I wonder if it is possible to least attain some rotational symmetry. That would give the tet a chiral bias, (clockwise would not be the same as CCW) but at least it would have some symmetry.

I'm not sure how to work this out, or, if it can't be done, why not. What am I encountering here that a highly symmetric object (a tetrahedron, or simply four point on a sphere) is broken by the addition of a bar at each vertex?

Last edited: