coby_rumblewood

- 7

- 1

- TL;DR Summary

- I have a high-power sealed subwoofer box with flanges resting on 30 Duro Isolating Pads. I want to secure it using #4 bolts, which pass through the flanges and have their own isolating pads beneath their heads. Will the subwoofer vibrations be transmitted to the base through the bolts, even with the isolating pads in place?

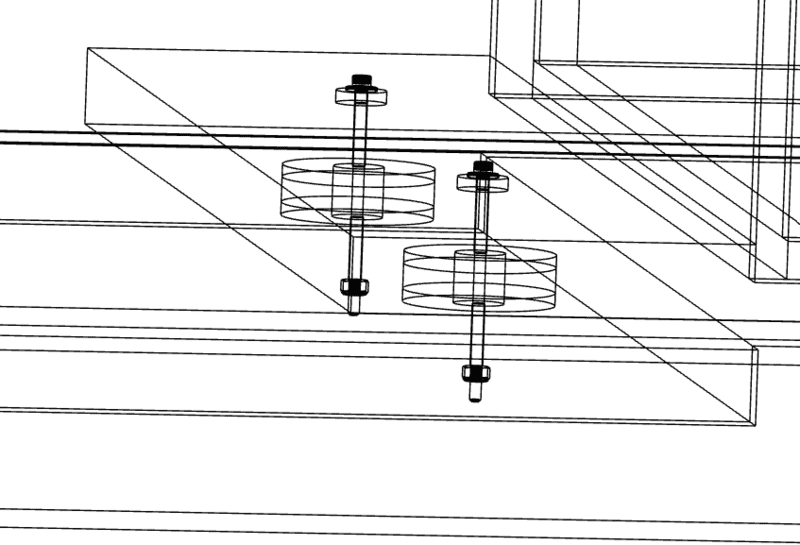

I have an acoustics question regarding mounting of a subwoofer enclosure, here is wireframe view of situation:

I have a sealed subwoofer box lets assume it is running high power 250 W RMS. It has flanges that come out that have 30 Duro Isolating Pads between the flanges and the base board below. Instead of letting it just rest there I want to securely mount it using some bolts, so I passed a #4 bolt through the top with a washer on smaller 30 Duro Isolating Pads, the flanges and plates have 1/8" holes which is bit larger than #4 bolt. Then a locknut on bottom. When the subwoofer shakes the box hard, will the vibrations pass through the bolt into the base structure? I believe because I put the bolt head on its own smaller pad it will not, but wanted to get other opinions.

I have a sealed subwoofer box lets assume it is running high power 250 W RMS. It has flanges that come out that have 30 Duro Isolating Pads between the flanges and the base board below. Instead of letting it just rest there I want to securely mount it using some bolts, so I passed a #4 bolt through the top with a washer on smaller 30 Duro Isolating Pads, the flanges and plates have 1/8" holes which is bit larger than #4 bolt. Then a locknut on bottom. When the subwoofer shakes the box hard, will the vibrations pass through the bolt into the base structure? I believe because I put the bolt head on its own smaller pad it will not, but wanted to get other opinions.