- #1

Jonathan_Concept

- 3

- 0

Hi all,

I'm an electrical engineer and I'm part way through the design of a little project and I'm struggling with a mechanical element which I'm hoping someone may be able to assist with. I'm going to keep the finer details out of this to keep things simple and just focus on the issue.

This is the mechanism in 'state 1':

- There's an arm (A) with a weight (B) attached to it. Both the weight of B and it's position along the arm can vary.

- The arm can rotate 90 degrees about point C (CCW from this 'state 1'). This is carried out using a servo D (this servo is not permanently coupled to the arm, it's just used to raise/lower the arm, it can then 'release' itself)

- There is an extension spring (E), which is in under very low tension when the mechanism is in this state (T1) so the servo will require minimal torque to lower the arm from it's vertical position.

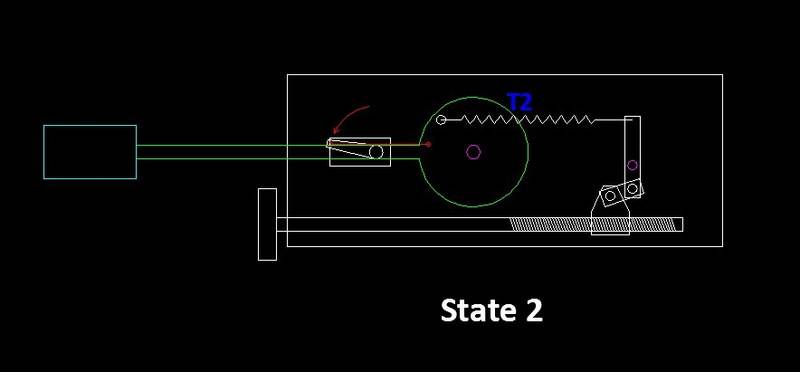

This is the mechanism in 'state 2':

- The servo has now lowered the arm, the spring is under increased tension (T2). T2 is enough to assist the servo in lifting the arm back up to state 1.

So, on to the problem! Rotating the adjustment knob (G) causes the tensioning assembly to pull back and pivot around point F which lengthens the spring. You can probably see where this is going, increasing the spring length gives increased tension when the mechanism is in state 2 (T2) to ease the load on the servo in raising the arm, but it also increases the tension when it's in state 1 (T1). So with heavier arms, adding enough spring tension to assist in lifting the arm from the horizontal position will result in too much tension in state 1 and the servo will be unable to lower the arm.

So what I think I need to do here is re-design the tensioning mechanism so that when we're in state 1 (vertical), the springs are always at the same length and as such in the same state of low tension, regardless of the adjustment that's been made to the tensioner by the user. It's only when the arm is lowered that the adjustment comes into play and gives you a final spring length that varies depending on how you've set the adjustment.

I hope this makes sense! There are just a couple of 'conditions' to bear in mind:

- The adjustment method for the user to adjust has to penetrate the enclosure at the rear (side 1), I can't make adjustments from other sides.

- Nothing's built yet but the general method of operation (servo actuated/spring assist) is set and can't be changed.

- The tensioner mechanism can be redesigned completely. As many pivot points/arms etc as required.

So there it is! I'd really appreciate any pointers you guys/gals could offer.

Thanks, Jonathan.

I'm an electrical engineer and I'm part way through the design of a little project and I'm struggling with a mechanical element which I'm hoping someone may be able to assist with. I'm going to keep the finer details out of this to keep things simple and just focus on the issue.

This is the mechanism in 'state 1':

- There's an arm (A) with a weight (B) attached to it. Both the weight of B and it's position along the arm can vary.

- The arm can rotate 90 degrees about point C (CCW from this 'state 1'). This is carried out using a servo D (this servo is not permanently coupled to the arm, it's just used to raise/lower the arm, it can then 'release' itself)

- There is an extension spring (E), which is in under very low tension when the mechanism is in this state (T1) so the servo will require minimal torque to lower the arm from it's vertical position.

This is the mechanism in 'state 2':

- The servo has now lowered the arm, the spring is under increased tension (T2). T2 is enough to assist the servo in lifting the arm back up to state 1.

So, on to the problem! Rotating the adjustment knob (G) causes the tensioning assembly to pull back and pivot around point F which lengthens the spring. You can probably see where this is going, increasing the spring length gives increased tension when the mechanism is in state 2 (T2) to ease the load on the servo in raising the arm, but it also increases the tension when it's in state 1 (T1). So with heavier arms, adding enough spring tension to assist in lifting the arm from the horizontal position will result in too much tension in state 1 and the servo will be unable to lower the arm.

So what I think I need to do here is re-design the tensioning mechanism so that when we're in state 1 (vertical), the springs are always at the same length and as such in the same state of low tension, regardless of the adjustment that's been made to the tensioner by the user. It's only when the arm is lowered that the adjustment comes into play and gives you a final spring length that varies depending on how you've set the adjustment.

I hope this makes sense! There are just a couple of 'conditions' to bear in mind:

- The adjustment method for the user to adjust has to penetrate the enclosure at the rear (side 1), I can't make adjustments from other sides.

- Nothing's built yet but the general method of operation (servo actuated/spring assist) is set and can't be changed.

- The tensioner mechanism can be redesigned completely. As many pivot points/arms etc as required.

So there it is! I'd really appreciate any pointers you guys/gals could offer.

Thanks, Jonathan.