Hydro2022

- 26

- 3

TL;DR Summary: Advanced hydrodynamic calculation- University Level

Calculate the necessary force of the hydraulic piston to empty the tank located at the bottom in the indicated time.

Hi all guys I'm new on this forum, and I write this post to ask you for help on a mechanical engineering, hydrodynamic, advanced level problem that I am not able to solve and I hope that some of you certainly better than me can to help.

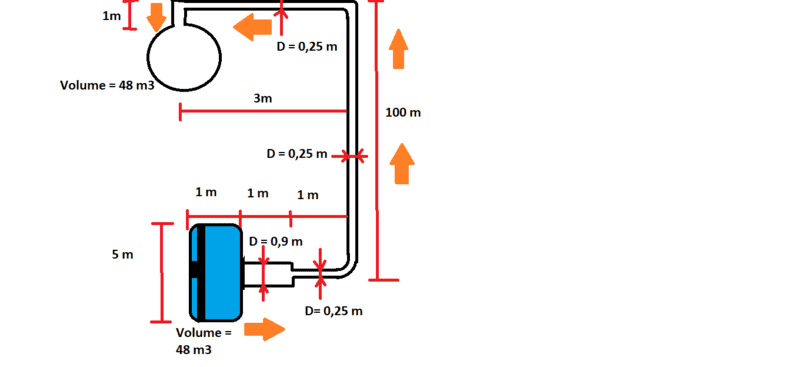

The problem is the following: (I enclose the hydraulic diagram, sorry I know it is not accurate, I did it again on the fly on the PC by copying it from the workbook, unfortunately it is not to scale but it should still be useful to understand the exercise).

Find the amount of force that must be applied to the hydraulic piston, placed in the blue tank at the bottom, containing 48 thousand liters of water to empty it in 25 seconds through a tube of 0.9m diameter and 1m length which narrows to a 0.25m diameter and 105m length connected up to the spherical tank also of 48 m3 placed at the top.

Fluid density of water at 20 degrees Celsius = 998.21 kg / m ^ 3

Dynamic viscosity of water at 20 degrees Celsius = 0.001002 Pa.s

tank bottom volume 48 m3 (5m * 9.6m * 1m)

while the tank at the top is always 48 m3 but it is spherical

style='font-size:16.0pt;font-family:"inherit",serif;color:#202124;mso-ansi-language:

EN'>='font-size:16.0pt;font-family:"inherit",serif;color:#202124'>

To calculate :

- Total force to be applied to the piston to empty the tank in the indicated time, considering the continuous and localized pressure drops (steel tube with very low roughness) and all frictions.

- Piston power in kWhPractically the piston has a stroke of 1 meter and it is necessary to calculate the force and power of the latter necessary to empty the tank at the bottom completely and consequently fill the spherical tank of the same volume placed at the top.

I tried to solve it, calculating the necessary force and I get about 3000 kN with a power of 1050 kWh, but I don't know where I am wrong and the result does not lead to that of the exercise. I calculated the head losses in the 2 narrowings, in the 3 curves, the continuous head losses and the necessary outflow force from the tank, to calculate the power I first calculated the work but nothing to do.

I thank anyone in advance who can solve the problem and help me.

Thank you :)

Calculate the necessary force of the hydraulic piston to empty the tank located at the bottom in the indicated time.

Hi all guys I'm new on this forum, and I write this post to ask you for help on a mechanical engineering, hydrodynamic, advanced level problem that I am not able to solve and I hope that some of you certainly better than me can to help.

The problem is the following: (I enclose the hydraulic diagram, sorry I know it is not accurate, I did it again on the fly on the PC by copying it from the workbook, unfortunately it is not to scale but it should still be useful to understand the exercise).

Find the amount of force that must be applied to the hydraulic piston, placed in the blue tank at the bottom, containing 48 thousand liters of water to empty it in 25 seconds through a tube of 0.9m diameter and 1m length which narrows to a 0.25m diameter and 105m length connected up to the spherical tank also of 48 m3 placed at the top.

Fluid density of water at 20 degrees Celsius = 998.21 kg / m ^ 3

Dynamic viscosity of water at 20 degrees Celsius = 0.001002 Pa.s

tank bottom volume 48 m3 (5m * 9.6m * 1m)

while the tank at the top is always 48 m3 but it is spherical

style='font-size:16.0pt;font-family:"inherit",serif;color:#202124;mso-ansi-language:

EN'>='font-size:16.0pt;font-family:"inherit",serif;color:#202124'>

To calculate :

- Total force to be applied to the piston to empty the tank in the indicated time, considering the continuous and localized pressure drops (steel tube with very low roughness) and all frictions.

- Piston power in kWhPractically the piston has a stroke of 1 meter and it is necessary to calculate the force and power of the latter necessary to empty the tank at the bottom completely and consequently fill the spherical tank of the same volume placed at the top.

I tried to solve it, calculating the necessary force and I get about 3000 kN with a power of 1050 kWh, but I don't know where I am wrong and the result does not lead to that of the exercise. I calculated the head losses in the 2 narrowings, in the 3 curves, the continuous head losses and the necessary outflow force from the tank, to calculate the power I first calculated the work but nothing to do.

I thank anyone in advance who can solve the problem and help me.

Thank you :)