Vigardo

- 87

- 7

- TL;DR

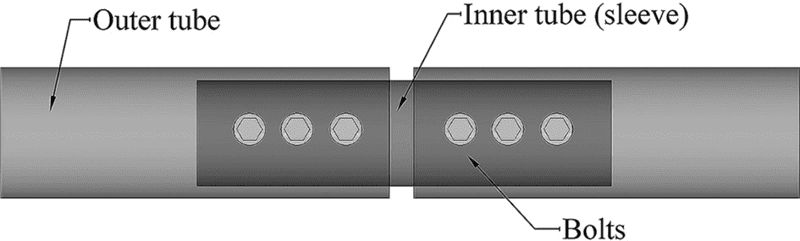

- What code should be used for designing Bolted Sleeve Connections for Circular (or Rectangular) Hollow cross-Sections?

Dear experts, thanks in advance for your kind help!

I have not found any provision or rule for designing bolted sleeve connections in EC1993-1-8 (Eurocode 3: Design of steel structures - Part 1-8: Design of joints) like the one shown in the figure:

I have just found some research paper about this kind of useful connections for Circular Hollow Sections: https://www.researchgate.net/publication/340793459_Bearing_failure_in_bolted_sleeve_connections_with_circular_hollow_sections_under_compression

Would you help me to find the appropriate design code? Any help is highly appreciated!

I have not found any provision or rule for designing bolted sleeve connections in EC1993-1-8 (Eurocode 3: Design of steel structures - Part 1-8: Design of joints) like the one shown in the figure:

I have just found some research paper about this kind of useful connections for Circular Hollow Sections: https://www.researchgate.net/publication/340793459_Bearing_failure_in_bolted_sleeve_connections_with_circular_hollow_sections_under_compression

Would you help me to find the appropriate design code? Any help is highly appreciated!