Jackolantern

- 28

- 4

- TL;DR

- half of aluminum beam is affected by weld heat, half isn't, will it hold up to the moment generated by the force?

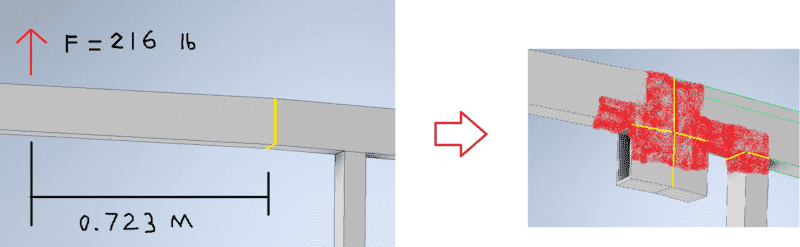

Hello All, I'm trying to figure out how to strengthen a box beam that's been welded to another box beam. In the photo on the left is 2 beams welded to each other, they are 2x1" Aluminum 6061-T6, with a 1/8" wall thickness. The yellow lines indicate the location of the weld. A force of 216 lbs is applied .723 meters away from the beam.

When aluminum 6061 T6 is welded, 5556 filler material can be used. The "Heat affected zone", or the area roughly 1 inch around a weld on aluminum will have greatly reduced mechanical properties, using filler material 5356, the yield strength of the HAZ is 15 ksi, compared to a yield strength of 35 ksi away from the HAZ. The filler metal has a yield strength close to >20ksi, so well focus on the weakest part of the weld- the HAZ.

If the maximum stress is calculated using sigma = My/Ixx

where M = 652.861 N-m, (it would be 694.995 N-m, but there is another force going downward that I forgot to include in the photo)

y = .0254 m (1")

Ixx = 1.380663 x 10^-7

Thus, the max stress is approximately 120 Mpa, which is greater than our HAZ yield strength of 15 ksi, or 103.42 MPa. So I need to beef up the area of the Heat affected zone. In the picture to the right of the arrow, you can see that I have proposed welding another 2x1 piece of aluminum 6061, thereby increasing the effective height of the beam in the area and increasing the local strength of the HAZ to well beyond the maximum stress.

But there's a problem, by welding more aluminum under it, we get new HAZs as indicated by the red splotches, on the bottom of our top spar we have a HAZ with only 15 ksi yield strength, but it transitions back to regular 6061 with 35 ksi yield strength just 1" up. My question is, how can I calculate or be sure that this new section- half HAZ, half normal, will hold up to the approximate moment of 652.861 N-m as calculate earlier?

When aluminum 6061 T6 is welded, 5556 filler material can be used. The "Heat affected zone", or the area roughly 1 inch around a weld on aluminum will have greatly reduced mechanical properties, using filler material 5356, the yield strength of the HAZ is 15 ksi, compared to a yield strength of 35 ksi away from the HAZ. The filler metal has a yield strength close to >20ksi, so well focus on the weakest part of the weld- the HAZ.

If the maximum stress is calculated using sigma = My/Ixx

where M = 652.861 N-m, (it would be 694.995 N-m, but there is another force going downward that I forgot to include in the photo)

y = .0254 m (1")

Ixx = 1.380663 x 10^-7

Thus, the max stress is approximately 120 Mpa, which is greater than our HAZ yield strength of 15 ksi, or 103.42 MPa. So I need to beef up the area of the Heat affected zone. In the picture to the right of the arrow, you can see that I have proposed welding another 2x1 piece of aluminum 6061, thereby increasing the effective height of the beam in the area and increasing the local strength of the HAZ to well beyond the maximum stress.

But there's a problem, by welding more aluminum under it, we get new HAZs as indicated by the red splotches, on the bottom of our top spar we have a HAZ with only 15 ksi yield strength, but it transitions back to regular 6061 with 35 ksi yield strength just 1" up. My question is, how can I calculate or be sure that this new section- half HAZ, half normal, will hold up to the approximate moment of 652.861 N-m as calculate earlier?