- #1

rollingstein

Gold Member

- 646

- 16

I pass a river with two bridges on it, right next to each other. One older, one newer.

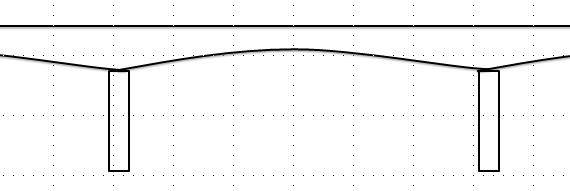

The newer one is all concrete construction & the shape of its spans makes intuitive sense to me i.e. minimum thickness at mid span. Like this sketch:

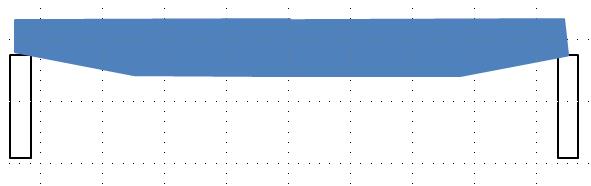

The older one has sort of the opposite shape with max girder thickness at mid span. Intuitively I cannot figure why this would be chosen so? Any thoughts? I have a sketch below.

If it matters the girders in the older bridge are steel with concrete piers.

Basically, does it make sense to have a beam that is thickest (deepest?) at the center? I find odd that two bridges will have the optimal beam shape exactly opposite.

The newer one is all concrete construction & the shape of its spans makes intuitive sense to me i.e. minimum thickness at mid span. Like this sketch:

The older one has sort of the opposite shape with max girder thickness at mid span. Intuitively I cannot figure why this would be chosen so? Any thoughts? I have a sketch below.

If it matters the girders in the older bridge are steel with concrete piers.

Basically, does it make sense to have a beam that is thickest (deepest?) at the center? I find odd that two bridges will have the optimal beam shape exactly opposite.