Feroyn

- 3

- 0

- TL;DR Summary

- I am building a motorcycle subframe, and I want to calculate the strength/durability of the structure. I need help doing that!

Hi!

I am an engineering graduate that took my bachelor's degree in Mechanical Engineering much too long ago, but I have forgotten a lot of the classical mechanics/mechanics of materials theory that I had learned many years ago. I am building a motorcycle right now, and I want to calculate the strength and durability of my build, to make sure I can use these aesthetics.

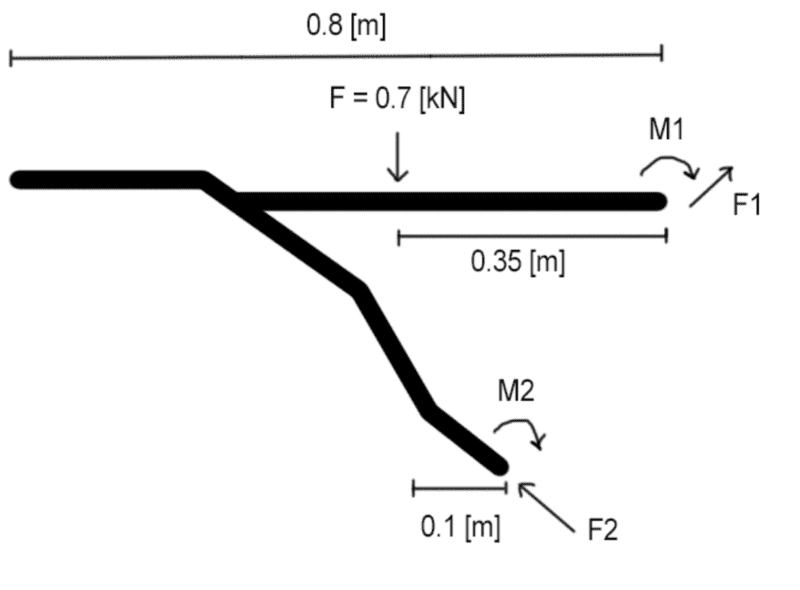

Here is the subframe that I want to calculate from. Assume the entire piece will be fully welded on the mainframe (welded at 4 spots).

Tubing is 25 mm in diameter, with a wall thickness of 1.6mm. Steel is EN 10305-3 E220 non-alloy low carbon steel.

Here's a quick side-profile sketch of my silly forces/moments. I'm assuming the force is at one spot to make it simpler (my weight).

Does anyone have any idea of how to approach this problem in both a classical mechanics (assuming the tubing won't deform/flex), and in a materials strength aspect (since it does flex and might be prone to bending IRL).

Sorry for the stupid question if this is rudimentary. Thank you for any help!

I am an engineering graduate that took my bachelor's degree in Mechanical Engineering much too long ago, but I have forgotten a lot of the classical mechanics/mechanics of materials theory that I had learned many years ago. I am building a motorcycle right now, and I want to calculate the strength and durability of my build, to make sure I can use these aesthetics.

Here is the subframe that I want to calculate from. Assume the entire piece will be fully welded on the mainframe (welded at 4 spots).

Tubing is 25 mm in diameter, with a wall thickness of 1.6mm. Steel is EN 10305-3 E220 non-alloy low carbon steel.

Here's a quick side-profile sketch of my silly forces/moments. I'm assuming the force is at one spot to make it simpler (my weight).

Does anyone have any idea of how to approach this problem in both a classical mechanics (assuming the tubing won't deform/flex), and in a materials strength aspect (since it does flex and might be prone to bending IRL).

Sorry for the stupid question if this is rudimentary. Thank you for any help!