- #1

thorq

- 9

- 0

Hi, I am trying to design a lifting platform for light duty loads (3d printing build platform) that only uses rotation for its actuation. I have a design that uses a mechanism similar to the slider crank and I want to maximize the total height the platform can travel.

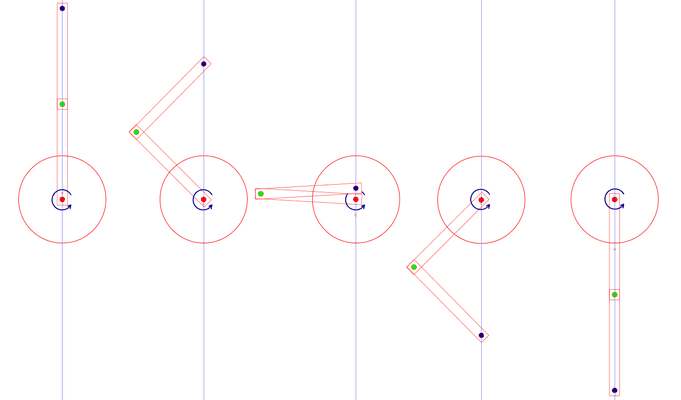

This is a sketch of my design:

The rotation is going to be executed by a motor at the red dot and my dilemma is about the behavior of the two arms when they reach the position at the middle of above image. I think this is called a singularity or dead point.

If the platform is going down, the way I have suggested in the sketch, at that point I see a weak mechanical position when the platform will tend to fall more than it should because of its weight. This is where I would loose precision in movement and I need a solution to overcome this.

A preloaded spring was suggested to me but I don't exactly know how should that be setup, to which direction is better? Is there any other (simple/cheap) solution employed by other such mechanisms/robot arms?

I am also thinking about having gears at the green dot ends of both arms but that would introduce backlash when the rotation would be reversed.

Thank you for your suggestions.

This is a sketch of my design:

The rotation is going to be executed by a motor at the red dot and my dilemma is about the behavior of the two arms when they reach the position at the middle of above image. I think this is called a singularity or dead point.

If the platform is going down, the way I have suggested in the sketch, at that point I see a weak mechanical position when the platform will tend to fall more than it should because of its weight. This is where I would loose precision in movement and I need a solution to overcome this.

A preloaded spring was suggested to me but I don't exactly know how should that be setup, to which direction is better? Is there any other (simple/cheap) solution employed by other such mechanisms/robot arms?

I am also thinking about having gears at the green dot ends of both arms but that would introduce backlash when the rotation would be reversed.

Thank you for your suggestions.