interestedperson

- 9

- 4

My high school physics days are long ago ;) This is not homework, well, other than it is work, at home.

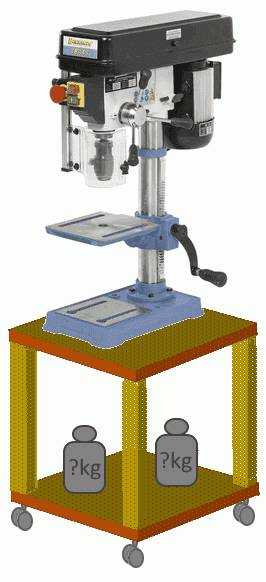

For a real application: Very space constrained "workshop", got a bench drill press, and want to build a table on wheels for it, to be able to move it into a corner when not needed.

Those wheels can each carry 100kg, got 4 of them, the drill press weights 54kg, so that should work for the wheels.

Now most of the weight is the motor unit, the cast iron foot of the thing will be bolted onto the table.

If I now apply a sideways force, like leaning against the motor case (or without extra weights, maybe sneezing at it!), the thing would fall over, if I chose table dimensions which are not much larger in the top surface area than the machine foot itself, says my gut feeling.

What I'd like to do is basically, compute what table dimensions I can get away with. The height does not have to be normal table height, working when sitting might be acceptable, it's only for occasional hobby stuff.

As drawn in the sketch below, I might add weights to the bottom of the table, to lower the overall center of mass.

(actually in the form of sandbags I have laying around, 25kg each, 2 might fit easily and leave the upper half for adding a tool drawer (optional))

I know the weights of the single parts of the machine. So I guess I calculate the center of mass of it all, including some assumed extra weight, make a simplified model where the left lower edge of the bottom of the table is a rotation axis, from it, a lever going to the center of the table bottom, from that, another lever going up to the center of mass. I also model in a sideways force with 1/2 my body weight or so, pressing at the motor case from the right, to the left, as if to make the whole thing fall over to the left side, around the axis that is the lower left edge of the table bottom.

Something like that?

Is there perhaps some free software to simulate that? There one could maybe see how quickly it would fall over if some excess force is applied sideways for a short period of time vs. whether it might just tilt by 2 degrees and recover... i.e. kinda like building it and trying intuitively whether it is sturdy enough, without having to waste material.

The apparent little holes are an artifact, the material is supposed to be solid wood.

The apparent little holes are an artifact, the material is supposed to be solid wood.

For a real application: Very space constrained "workshop", got a bench drill press, and want to build a table on wheels for it, to be able to move it into a corner when not needed.

Those wheels can each carry 100kg, got 4 of them, the drill press weights 54kg, so that should work for the wheels.

Now most of the weight is the motor unit, the cast iron foot of the thing will be bolted onto the table.

If I now apply a sideways force, like leaning against the motor case (or without extra weights, maybe sneezing at it!), the thing would fall over, if I chose table dimensions which are not much larger in the top surface area than the machine foot itself, says my gut feeling.

What I'd like to do is basically, compute what table dimensions I can get away with. The height does not have to be normal table height, working when sitting might be acceptable, it's only for occasional hobby stuff.

As drawn in the sketch below, I might add weights to the bottom of the table, to lower the overall center of mass.

(actually in the form of sandbags I have laying around, 25kg each, 2 might fit easily and leave the upper half for adding a tool drawer (optional))

I know the weights of the single parts of the machine. So I guess I calculate the center of mass of it all, including some assumed extra weight, make a simplified model where the left lower edge of the bottom of the table is a rotation axis, from it, a lever going to the center of the table bottom, from that, another lever going up to the center of mass. I also model in a sideways force with 1/2 my body weight or so, pressing at the motor case from the right, to the left, as if to make the whole thing fall over to the left side, around the axis that is the lower left edge of the table bottom.

Something like that?

Is there perhaps some free software to simulate that? There one could maybe see how quickly it would fall over if some excess force is applied sideways for a short period of time vs. whether it might just tilt by 2 degrees and recover... i.e. kinda like building it and trying intuitively whether it is sturdy enough, without having to waste material.