- #1

Travis T

- 18

- 2

- TL;DR Summary

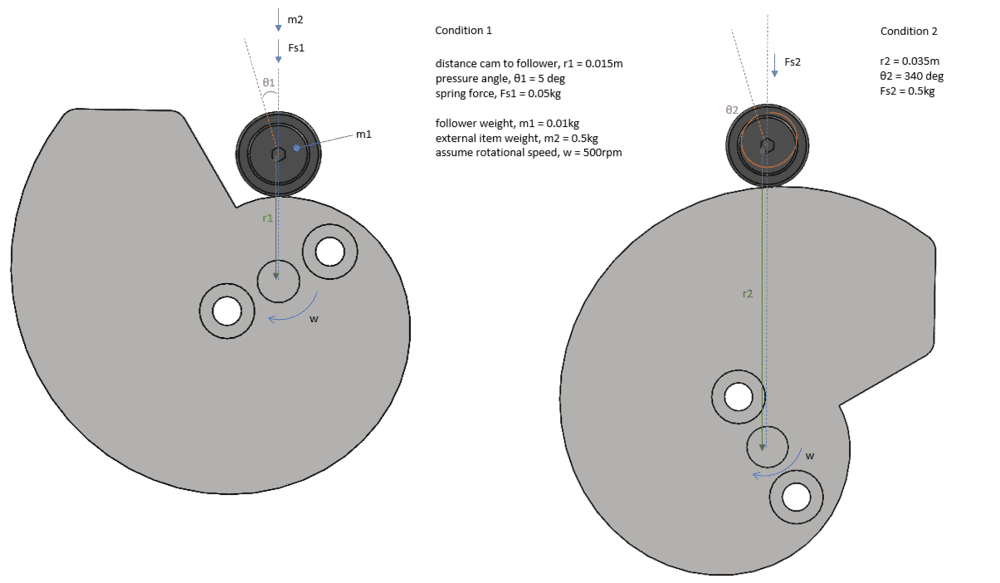

- Would like to check the design of snail cam require how much motor rated torque?

Hi all,

I'm currently designing a cam mechanism.

Would like to check how much motor rated torque required for the following design of snail cam ?

To ease calculation, i have include some assumed factor as below. Two extreme condition (rotation degree) to compare.

What is the motor rated torque required for the design? (is 0.30Nm enough?)

*please let know if any factor missing or not logic.

*would like to have estimation for motor selection only, thus to simplify, insignificant and complicated factor can be ignore

I'm currently designing a cam mechanism.

Would like to check how much motor rated torque required for the following design of snail cam ?

To ease calculation, i have include some assumed factor as below. Two extreme condition (rotation degree) to compare.

What is the motor rated torque required for the design? (is 0.30Nm enough?)

*please let know if any factor missing or not logic.

*would like to have estimation for motor selection only, thus to simplify, insignificant and complicated factor can be ignore