- #1

Wilson123

- 58

- 2

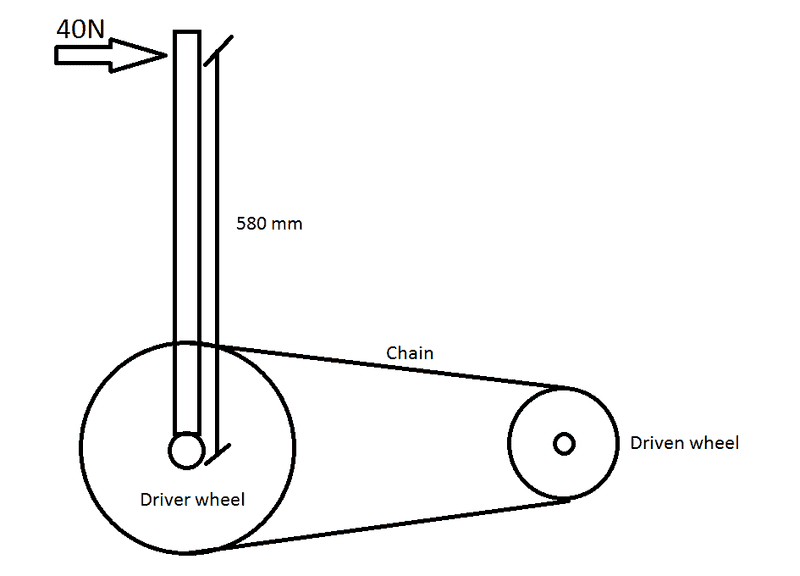

I'm trying to calculate the required gear sizes for the system shown below:

The driven wheel is connected to a 600mm diameter bicycle wheel and the driver wheel connected to a 580 mm long lever arm which has a forward driving force of 40 N.

I want to calculate the most efficient sizing of both wheels to provide the most torque to the driven wheel from the driver wheel.

To do this I think I am correct in needing to know the force which the driven wheel needs to provide to the bicycle wheel, therefore I believe the rolling resistance coefficient of the surface needs to be defined, I have found this to be 0.008 for the required terrain.

I think I have all the required information here to solve this problem however I am struggling to "connect the dots" and be provided with the sizing for both the driver wheel and driven wheel.

Any help is greatly appreciated and I will try clarify anything which is unclear if more information is needed!

The driven wheel is connected to a 600mm diameter bicycle wheel and the driver wheel connected to a 580 mm long lever arm which has a forward driving force of 40 N.

I want to calculate the most efficient sizing of both wheels to provide the most torque to the driven wheel from the driver wheel.

To do this I think I am correct in needing to know the force which the driven wheel needs to provide to the bicycle wheel, therefore I believe the rolling resistance coefficient of the surface needs to be defined, I have found this to be 0.008 for the required terrain.

I think I have all the required information here to solve this problem however I am struggling to "connect the dots" and be provided with the sizing for both the driver wheel and driven wheel.

Any help is greatly appreciated and I will try clarify anything which is unclear if more information is needed!