kingneptune11

- 10

- 0

Hello all,

I am trying to figure out how to calculate the torque on a cam shaft.

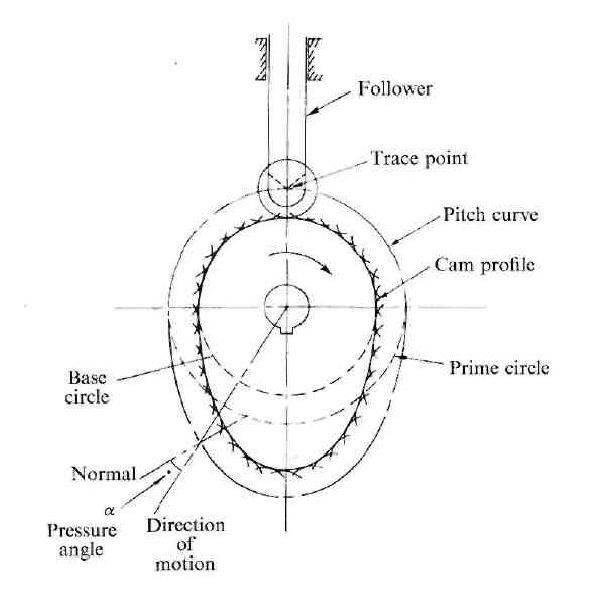

Say we are looking at this cam and cam follower:

If we know that the total force downward caused by the cam follower is, let's say, 50lb, how do I determine the torque required of the cam shaft to rotate the cam at any given cam angle? I was under the impression it was the following:

Cam Shaft Torque = (Normal Force of cam follower on cam)(distance from cam shaft center to point of contact between cam and cam follower)(tan(pressure angle))

However, I am still confused about this. I cannot seem to find any cam design references online that discuss the calculations of the cam shaft torque. I can only find information regarding the velocity profiles of the cam. Can anyone help me with this? Or maybe can someone point me in the direction of some good online references that discuss this topic?

Thank you.

I am trying to figure out how to calculate the torque on a cam shaft.

Say we are looking at this cam and cam follower:

If we know that the total force downward caused by the cam follower is, let's say, 50lb, how do I determine the torque required of the cam shaft to rotate the cam at any given cam angle? I was under the impression it was the following:

Cam Shaft Torque = (Normal Force of cam follower on cam)(distance from cam shaft center to point of contact between cam and cam follower)(tan(pressure angle))

However, I am still confused about this. I cannot seem to find any cam design references online that discuss the calculations of the cam shaft torque. I can only find information regarding the velocity profiles of the cam. Can anyone help me with this? Or maybe can someone point me in the direction of some good online references that discuss this topic?

Thank you.

)

)