Jeremy Sawatzky

- 33

- 13

- TL;DR

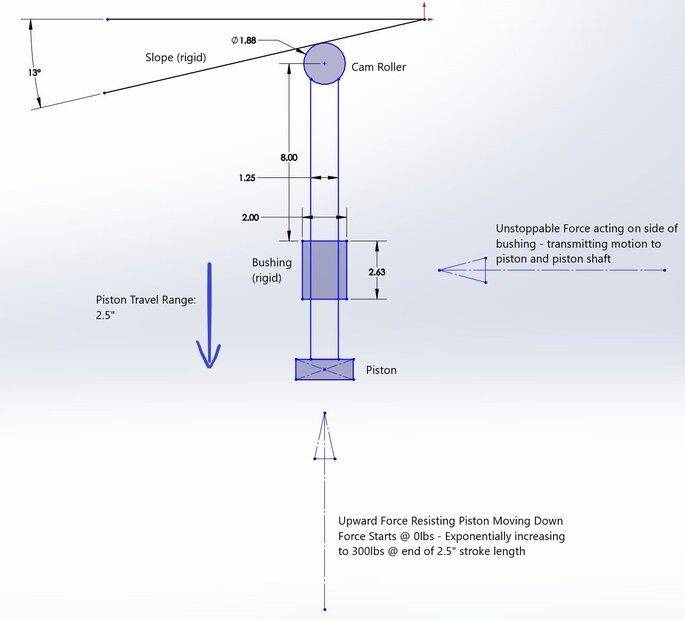

- I have a cam roller on a sloped surface providing a pressing force to a product. How aggressive can my cam surface be without destroying the linear bearing prematurely?

I have a machine I am designing that for all intensive descriptions, is a simple press designed to compress loose product into a puck like shape.

The press force comes from a roller bearing mounted to a piston shaft, the rod sliding through a rigid linear bearing and the piston on the end of the shaft acting on the product. The roller bearing is rolling on a surface that gradually slopes downward imparting a downward force but also a sideways force on the piston rod and as such the linear bushing.

My goal is to determine how aggressive of a slope I can have the roller bearing interacting with. as the slope angle increases, so do the side forces on the piston shaft, so do the forces on the bushing. I recognize that I am dealing with point pressures on the top and bottom edges of the bushing.

Lastly, the forces all originate from the bushing. The bushing imparts the side force onto the piston rod. The sloped surface that the roller rides on is mounted rigidly.

Thank you!

The press force comes from a roller bearing mounted to a piston shaft, the rod sliding through a rigid linear bearing and the piston on the end of the shaft acting on the product. The roller bearing is rolling on a surface that gradually slopes downward imparting a downward force but also a sideways force on the piston rod and as such the linear bushing.

My goal is to determine how aggressive of a slope I can have the roller bearing interacting with. as the slope angle increases, so do the side forces on the piston shaft, so do the forces on the bushing. I recognize that I am dealing with point pressures on the top and bottom edges of the bushing.

Lastly, the forces all originate from the bushing. The bushing imparts the side force onto the piston rod. The sloped surface that the roller rides on is mounted rigidly.

Thank you!