dakotahm88

- 19

- 2

- TL;DR Summary

- Two sprocket chain system help!

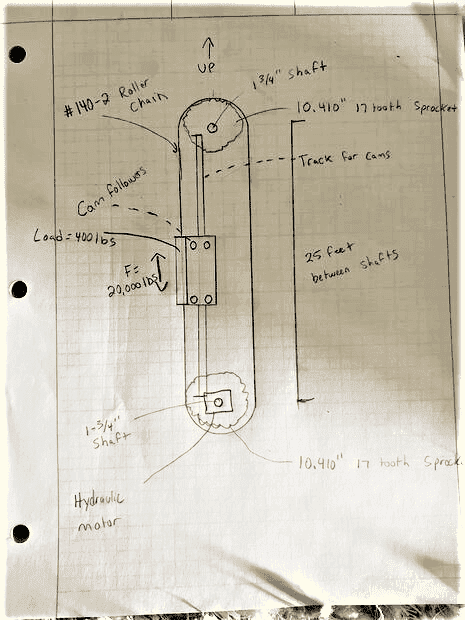

[Mentor Note -- postprocessed attached image for clarity]

Hello!

Looking for a formula(s) on how I can determine the Torque and RPM needed on the chain (by hydraulic motor) to move the load in the illustration at 240 inches per minute.

The load will vary, so I won’t ever really need to push or pull 20,000lbs at that speed, but I do need to be able to reach that speed in times of no load.

The skate that Carries the load is fixed to an I-beam with cam followers to help reduce friction between the skate and beam it slides on.

Hello!

Looking for a formula(s) on how I can determine the Torque and RPM needed on the chain (by hydraulic motor) to move the load in the illustration at 240 inches per minute.

The load will vary, so I won’t ever really need to push or pull 20,000lbs at that speed, but I do need to be able to reach that speed in times of no load.

The skate that Carries the load is fixed to an I-beam with cam followers to help reduce friction between the skate and beam it slides on.