- #1

MillGuy

- 11

- 10

- TL;DR Summary

- I've created a macro program used by a CNC milling machine to cut threads in a hole. It works when I arcs into the minor diameter of the thread at 90 deg. (alpha angle) but not when I decrease the alpha angle.

I've created a macro program used by a CNC milling machine to cut threads in a hole. I like to use macro programs because it allows me to use the same macro for any different size of feature just by changing a few variables. I like to first test out my macro programs using a spread sheet to plug in all of my formulas and check the outputs.

Everything works like it should when my alpha angle ( where the cutter enters the minor diameter) is 90 degrees from where the cutter will be cutting at the full diameter of the thread.

The problem is when I decrease my alpha angle, 45 deg. for example, the radius of the tangential arc is incorrect.

I don't have CAD software, and I don't want to be bothering the Engineers and Mech Tech's at my shop every time I want to visualize it, so I just use a protractor and a drafting compass to draw a bunch of circles

Most of the work we do is in Imperial measurements so our machines are in inches (lame, I know)

My Machine controller doesn't have arcsin or arccos functions just arctan, so I have to go the long way around to calculate angles

Example:

[VN=1.5] (THREAD NOMINAL DIA.)

[VM=1.375] (THREAD MINOR DIA.)

[VP=.125] (PITCH)

[VD=1.000] (TOOL DIA.)

[VC=.02] (MINOR DIA. CLEARANCE AMOUNT)

[VA=90.] (ENTRY ANGLE/ALFA ANGLE)

[VH=[[[VM*VM]/[360./VA]]+[[VN*VN]/[360./VA]]]/VN] (RADIUS OF TANGENTIAL ARC)

[VB=VA+ATAN[[SQRT[[[VN/2]*[VN/2]]-[[[VN/2]-VC]*[[VN/2]-VC]]]]/[[VN/2]-VC]]] (BETA ANGLE)

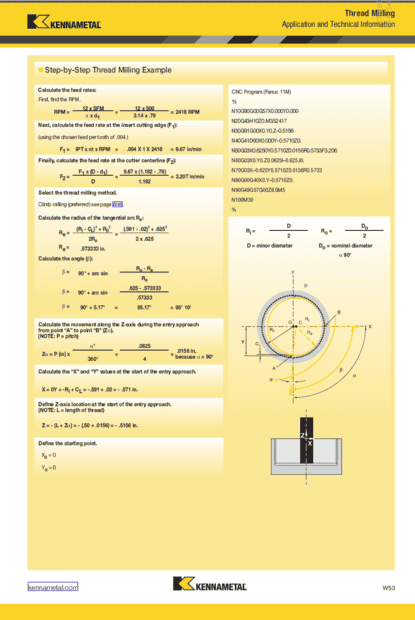

Below is the example I'm basing my macro on

Everything works like it should when my alpha angle ( where the cutter enters the minor diameter) is 90 degrees from where the cutter will be cutting at the full diameter of the thread.

The problem is when I decrease my alpha angle, 45 deg. for example, the radius of the tangential arc is incorrect.

I don't have CAD software, and I don't want to be bothering the Engineers and Mech Tech's at my shop every time I want to visualize it, so I just use a protractor and a drafting compass to draw a bunch of circles

Most of the work we do is in Imperial measurements so our machines are in inches (lame, I know)

My Machine controller doesn't have arcsin or arccos functions just arctan, so I have to go the long way around to calculate angles

Example:

[VN=1.5] (THREAD NOMINAL DIA.)

[VM=1.375] (THREAD MINOR DIA.)

[VP=.125] (PITCH)

[VD=1.000] (TOOL DIA.)

[VC=.02] (MINOR DIA. CLEARANCE AMOUNT)

[VA=90.] (ENTRY ANGLE/ALFA ANGLE)

[VH=[[[VM*VM]/[360./VA]]+[[VN*VN]/[360./VA]]]/VN] (RADIUS OF TANGENTIAL ARC)

[VB=VA+ATAN[[SQRT[[[VN/2]*[VN/2]]-[[[VN/2]-VC]*[[VN/2]-VC]]]]/[[VN/2]-VC]]] (BETA ANGLE)

Below is the example I'm basing my macro on

Last edited by a moderator: