Ironwood

- 6

- 1

- TL;DR Summary

- How much compressed air will it take to push a given volume of water up a given height at a certain rate?

Greeting,

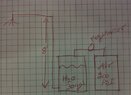

I have been noodling on this problem for a bit and was hoping to have some input from this form. what volume of compressed air, at 200 PSI, will it take to push lets say 30 gallons of water 8 feet up a 3/4" pipe at a minimum of 8 gpm with a minimum pressure of 8psi at the top if there is a regulated pressure between the two tanks? so imagine an air tank with a pipe running from it to the top of a pressure rated water tank, and from the water tank a pipe running from the bottom up 8 feet. How much air, volumetrically, will there need to be in the first tank to push all 30 gallons up the pipe at the minimum pressure and not run out of air by the end. and also how long will it take?

I have been noodling on this problem for a bit and was hoping to have some input from this form. what volume of compressed air, at 200 PSI, will it take to push lets say 30 gallons of water 8 feet up a 3/4" pipe at a minimum of 8 gpm with a minimum pressure of 8psi at the top if there is a regulated pressure between the two tanks? so imagine an air tank with a pipe running from it to the top of a pressure rated water tank, and from the water tank a pipe running from the bottom up 8 feet. How much air, volumetrically, will there need to be in the first tank to push all 30 gallons up the pipe at the minimum pressure and not run out of air by the end. and also how long will it take?