Engineer_Kosyakova

- 4

- 1

- TL;DR Summary

- Simulation of electron beam heating (SEM) of an InSb sample with nitrogen cooling. It is not possible to calculate the heating during cooling in COMSOL. Maybe I'm using the wrong modules for cooling? Without cooling, the heating counts correctly.

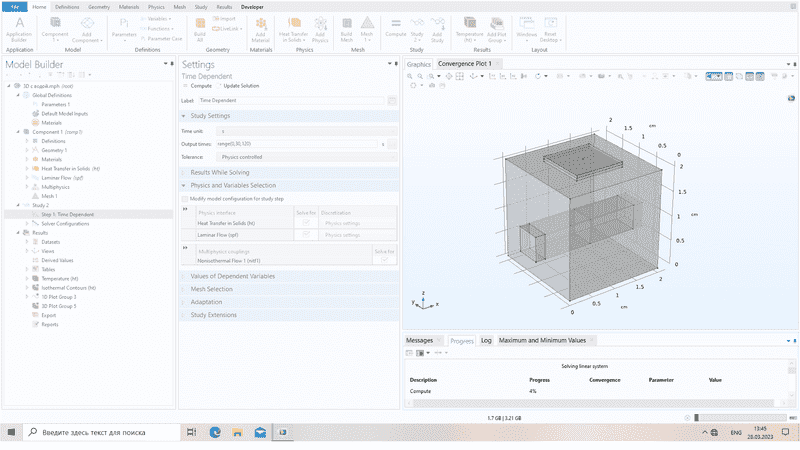

The InSb sample (parameters 10x10x0.5 mm) is glued with silver glue to a cooled copper table. Liquid nitrogen passes through the table. While the model is at a temperature of 300 K and at a normal pressure of 1 bar. The sample is affected by a beam of electrons, which causes the surface to heat up. Modules used in COMSOL:

1. Heat transfer in Solids

2. Laminar Flow

3. Multyphysics (auto)

It is not possible to calculate the heating during cooling. Nitrogen Dynamic Viscosity - 161,4 E-6 (Pa*s)

1. Heat transfer in Solids

2. Laminar Flow

3. Multyphysics (auto)

It is not possible to calculate the heating during cooling. Nitrogen Dynamic Viscosity - 161,4 E-6 (Pa*s)