Nathanwest58

- 12

- 4

- TL;DR Summary

- How can I be reasonably confident that FEA is giving me reasonably accurate stress values?

Hi all,

I’m trying to get a better understanding of ANSYS as I don’t have a lot of experience with it. My question is with respect to a static structural analysis of a solid part: “how can I be reasonably confident that FEA is giving me reasonably accurate stress values?”

I’ll analyse a cantilever beam of length 1000mm, with a base of 50mm and height of 25mm. A 1000 N load is applied at the free-end of the beam. Young’s modulus is 200 GPa.

I calculate a bending stress of 192 MPa at the fixed end, and a deflection at the free-end of 25.6mm. Total strain energy is 12.8 J.

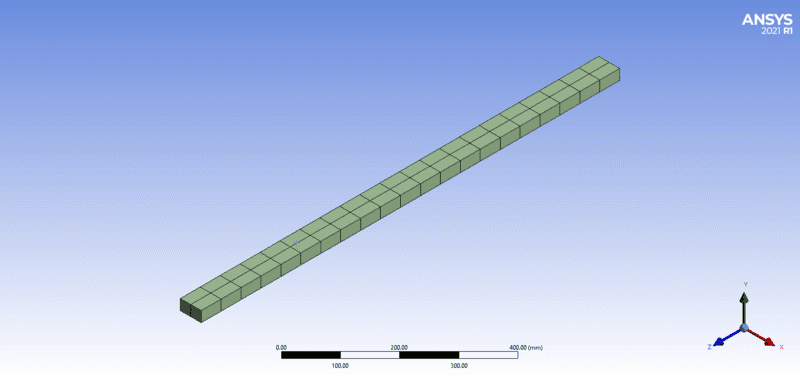

I add total deformation, equivalent stress, and strain energy as solution outputs. I don’t apply any mesh methods or controls and just let the software do its thing for the first run, and it produces the following mesh.

Running the solver and I’ve tabulated my calculations compared to ANSYS results.

The difference in stress is approximately 5%. Not too big a deal as the material yield stress is 250 MPa. I check the element quality.

All elements have the same quality of approximately 0.74, and I’m assuming that this is what is causing the discrepancy in the stress? I now apply a body sizing control to the mesh and reduce the element size from 12.5mm to 6.25mm. I expect that the stress will increase as the element size decreases. Second run tabulated.

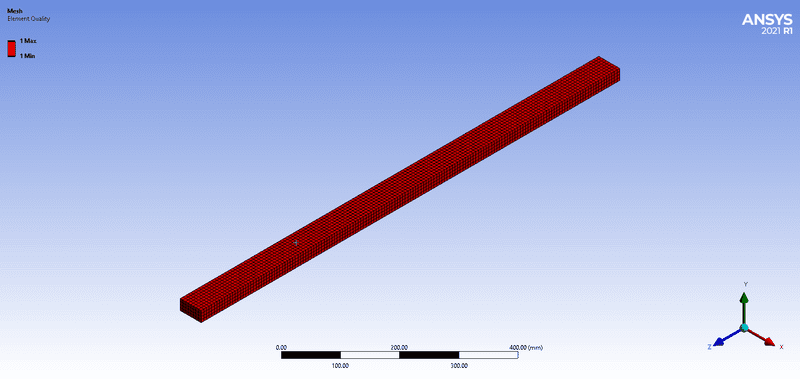

Element quality check on second run.

All elements have perfect quality.

The stress increased as expected. But the strain energy and deformation have barely changed, the element quality is now apparently perfect.

This is a very basic example with simple geometry. I have calculated values for stress, displacement and strain energy so I can compare them with ANSYS. However, if I want to run an analysis on a more complex part where I’m a) not able to perform hand calculations, b) have what appears to be a converged deformation solution and no change in strain energy from one element size to another, c) have very high quality elements, how am I to have any confidence with the stress values ANSYS is giving me? So to restate the original question: “how can I be reasonably confident that FEA is giving me reasonably accurate stress values?”

Any help and insight is greatly appreciated.

I’m trying to get a better understanding of ANSYS as I don’t have a lot of experience with it. My question is with respect to a static structural analysis of a solid part: “how can I be reasonably confident that FEA is giving me reasonably accurate stress values?”

I’ll analyse a cantilever beam of length 1000mm, with a base of 50mm and height of 25mm. A 1000 N load is applied at the free-end of the beam. Young’s modulus is 200 GPa.

I calculate a bending stress of 192 MPa at the fixed end, and a deflection at the free-end of 25.6mm. Total strain energy is 12.8 J.

I add total deformation, equivalent stress, and strain energy as solution outputs. I don’t apply any mesh methods or controls and just let the software do its thing for the first run, and it produces the following mesh.

Running the solver and I’ve tabulated my calculations compared to ANSYS results.

Calculated | ANSYS | Difference | % difference | |

| Deformation (mm) | 25.6 | 25.5 | 0.1 | 0.4% |

| Stress (MPa) | 192 | 183.1 | 8.9 | 4.7% |

| Strain energy, total (J) | 12.8 | 12.7 | 0.1 | 0.8% |

The difference in stress is approximately 5%. Not too big a deal as the material yield stress is 250 MPa. I check the element quality.

All elements have the same quality of approximately 0.74, and I’m assuming that this is what is causing the discrepancy in the stress? I now apply a body sizing control to the mesh and reduce the element size from 12.5mm to 6.25mm. I expect that the stress will increase as the element size decreases. Second run tabulated.

Calculated | 1st run | 2nd run | |

| Deformation (mm) | 25.6 | 25.5 | 25.5 |

| Stress (MPa) | 192 | 183.1 | 199 |

| Strain energy, total (J) | 12.8 | 12.7 | 12.7 |

All elements have perfect quality.

The stress increased as expected. But the strain energy and deformation have barely changed, the element quality is now apparently perfect.

This is a very basic example with simple geometry. I have calculated values for stress, displacement and strain energy so I can compare them with ANSYS. However, if I want to run an analysis on a more complex part where I’m a) not able to perform hand calculations, b) have what appears to be a converged deformation solution and no change in strain energy from one element size to another, c) have very high quality elements, how am I to have any confidence with the stress values ANSYS is giving me? So to restate the original question: “how can I be reasonably confident that FEA is giving me reasonably accurate stress values?”

Any help and insight is greatly appreciated.