MechEn9ineer

- 5

- 2

- TL;DR Summary

- Evaluation of concept idea for lifting 750 ton using rack and pinion combined with lead screw

Hi everyone,

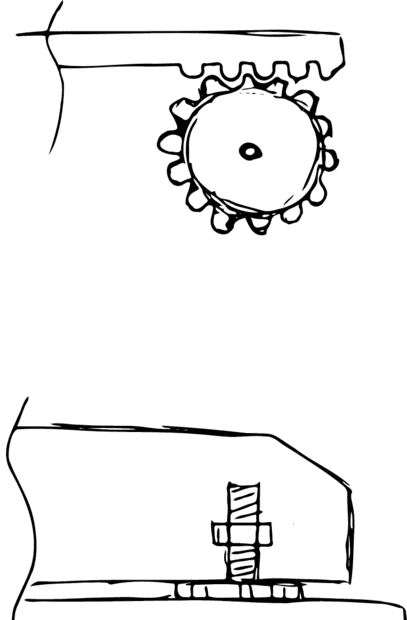

I am in concept phase of designing a lifting mean for 750 ton, I have many ideas using hydraulics which I could cost estimate online. However, one of the ideas is using rack and pinion combined with lead screw with its sizes determined from rough stress calculations. So, does anyone have an idea how to cost estimate the following?

1) Screw and nut

- Diameter = 160 mm

- Length < 1 m

- Lead angle = 10 degrees

- Yield stress > 235 MPa

2) Rack and Pinion

- Module = 40

- No. of teeth = 10

- Pinion thickness = 200 mm

- Pressure angle = 20 degrees

- Rack Length = 8 meter

- Yield stress > 235 MPa

I am in concept phase of designing a lifting mean for 750 ton, I have many ideas using hydraulics which I could cost estimate online. However, one of the ideas is using rack and pinion combined with lead screw with its sizes determined from rough stress calculations. So, does anyone have an idea how to cost estimate the following?

1) Screw and nut

- Diameter = 160 mm

- Length < 1 m

- Lead angle = 10 degrees

- Yield stress > 235 MPa

2) Rack and Pinion

- Module = 40

- No. of teeth = 10

- Pinion thickness = 200 mm

- Pressure angle = 20 degrees

- Rack Length = 8 meter

- Yield stress > 235 MPa