- #1

Roy S Ramirez

- 24

- 4

- TL;DR Summary

- I have no idea how to properly size an NPT hole.

Hello everybody!

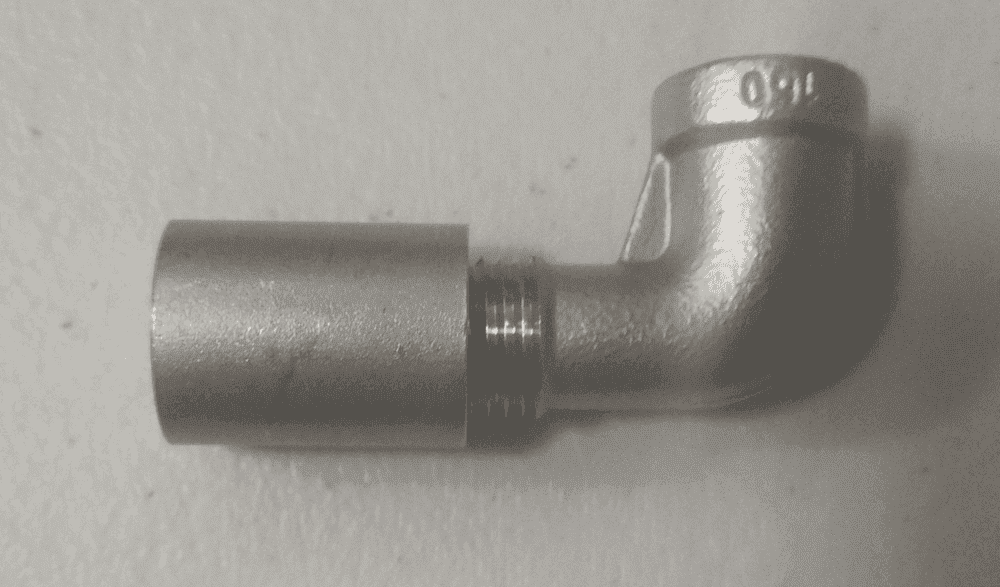

I've notice that when using NPT fittings, the female fittings usually doesn't take all of the male threads:

This has never bothered me since these are commercial fittings and the engineers who designed them know what they are doing. But now, I need to make NPT holes in a metallic plate, and I'm concerned about this. Since the hole should be tapered, I noticed that the deeper I get the tap, the more threads the hole takes. For example, for a 1/8" NPT fitting, I drilled and tapped a hole in a 24 mm thick piece of wood and was able to screw it all in:

But if I drill and tap a less deeper hole (closer to the actual length of the fitting), I get less threads in like in image 1. So it seems like the deeper I go the better, but this means making lots of threads that don't get use. In the second picture the fitting has a length of 10 mm while the hole is about 24 mm; that leaves 14 mm of unused threads!

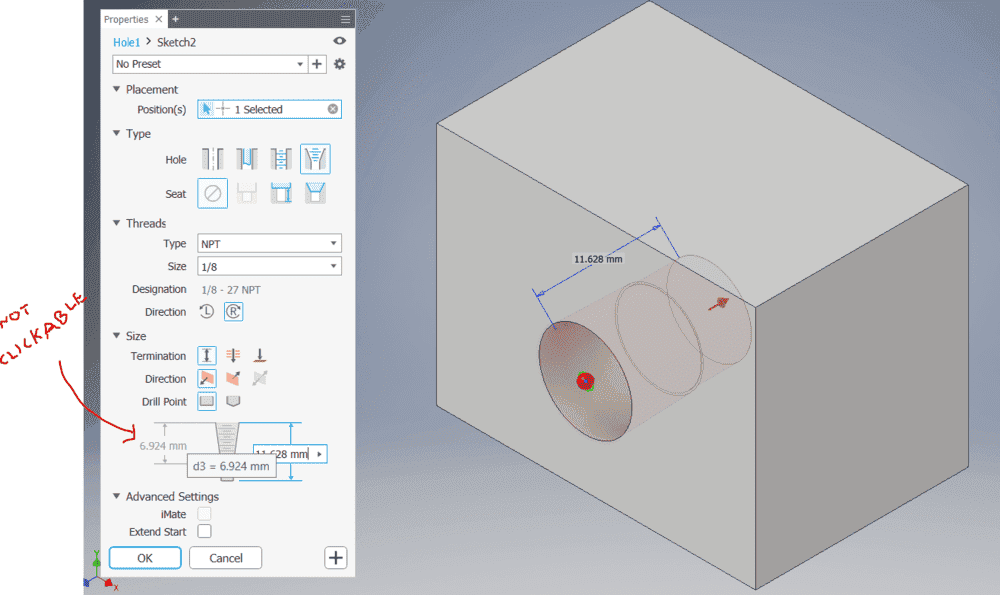

Moreover, Autodesk Inventor makes me more confused. Whenever I try to add an NPT hole, it doesn't let me change the threaded section's depth:

So my question is how do I design 1/8" NPT holes?

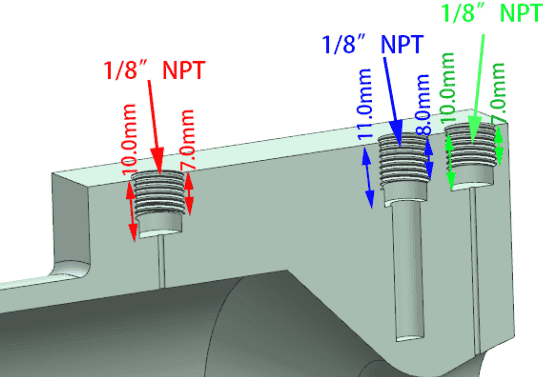

This is the part I'm manufacturing, I have three fittings like the one in image 2, and I would like to be able to fully screw them in in these three holes:

Thank you for your help!

Roy

I've notice that when using NPT fittings, the female fittings usually doesn't take all of the male threads:

This has never bothered me since these are commercial fittings and the engineers who designed them know what they are doing. But now, I need to make NPT holes in a metallic plate, and I'm concerned about this. Since the hole should be tapered, I noticed that the deeper I get the tap, the more threads the hole takes. For example, for a 1/8" NPT fitting, I drilled and tapped a hole in a 24 mm thick piece of wood and was able to screw it all in:

But if I drill and tap a less deeper hole (closer to the actual length of the fitting), I get less threads in like in image 1. So it seems like the deeper I go the better, but this means making lots of threads that don't get use. In the second picture the fitting has a length of 10 mm while the hole is about 24 mm; that leaves 14 mm of unused threads!

Moreover, Autodesk Inventor makes me more confused. Whenever I try to add an NPT hole, it doesn't let me change the threaded section's depth:

So my question is how do I design 1/8" NPT holes?

This is the part I'm manufacturing, I have three fittings like the one in image 2, and I would like to be able to fully screw them in in these three holes:

Thank you for your help!

Roy