- #1

Luth

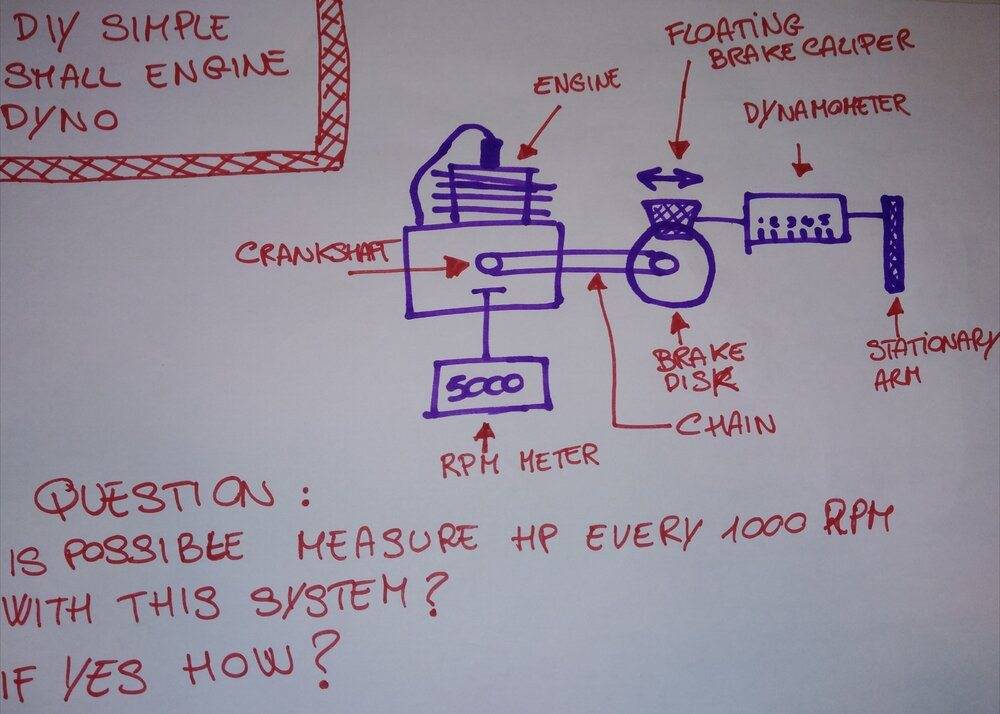

Hi, I have to measure the HP of a small engine at the crankshaft. The only usable things are.

A dinamometer

A brake disk

An rpm meter

The brake caliper is floating so when we apply de load it pull the dinamometer.

The rpm meter show the revolution during the load apply. It can works?

How I should do the measure to find the HP every 1000 rpm?

Here the picture of the project.

Please if is possible show me the procedure step by step.

Thanks!

Luth

A dinamometer

A brake disk

An rpm meter

The brake caliper is floating so when we apply de load it pull the dinamometer.

The rpm meter show the revolution during the load apply. It can works?

How I should do the measure to find the HP every 1000 rpm?

Here the picture of the project.

Please if is possible show me the procedure step by step.

Thanks!

Luth