GTC

- 9

- 0

- TL;DR Summary

- Relay circuit, which inhibits hoist operation, is a mystery to me.

I have been given an electrical chain hoist to repair. The symptom is that it suddenly stopped working.

I have checked the motor's windings and they each show similar DC resistance of 0.0018 ohms.

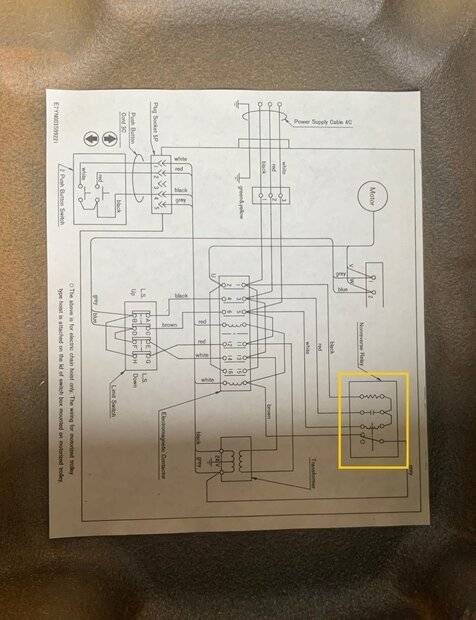

I have attached the schematic (dunno why it was rotated 90 degrees during the upload).

The hoist operates from 3-phase mains. Its up and down motion is controlled via push buttons which are supplied with 24 volts AC from a step-down transformer connected across 2 phases. The push buttons operate a reversing contactor which, via the up/down limit switch, swaps one of the motor's phases to effect forward and reverse modes. I have ascertained that the 24 volt circuit is working correctly as is the reversing contactor.

I have also ascertained that the reason the hoist is not operating is that the normally-closed relay that I have highlighted in the schematic is energized as soon as power is applied to the hoist, the effect of which is that the 24 volt supply is interrupted thus rendering the up/down control function inactive.

I don't understand the highlighted area of this circuit and would appreciate help with it. Specifically, which condition would leave the relay in its normally-closed position (and thus allow the hoist to operate) as opposed to the condition that causes it to go to normally-open (and thus inhibit hoist operation)?

Note that all 3 phases are connected to it. The coil is rated at 220V AC, i.e. the voltage of one of the phases.

I have checked the motor's windings and they each show similar DC resistance of 0.0018 ohms.

I have attached the schematic (dunno why it was rotated 90 degrees during the upload).

The hoist operates from 3-phase mains. Its up and down motion is controlled via push buttons which are supplied with 24 volts AC from a step-down transformer connected across 2 phases. The push buttons operate a reversing contactor which, via the up/down limit switch, swaps one of the motor's phases to effect forward and reverse modes. I have ascertained that the 24 volt circuit is working correctly as is the reversing contactor.

I have also ascertained that the reason the hoist is not operating is that the normally-closed relay that I have highlighted in the schematic is energized as soon as power is applied to the hoist, the effect of which is that the 24 volt supply is interrupted thus rendering the up/down control function inactive.

I don't understand the highlighted area of this circuit and would appreciate help with it. Specifically, which condition would leave the relay in its normally-closed position (and thus allow the hoist to operate) as opposed to the condition that causes it to go to normally-open (and thus inhibit hoist operation)?

Note that all 3 phases are connected to it. The coil is rated at 220V AC, i.e. the voltage of one of the phases.