- #1

serbring

- 271

- 2

Hi all,

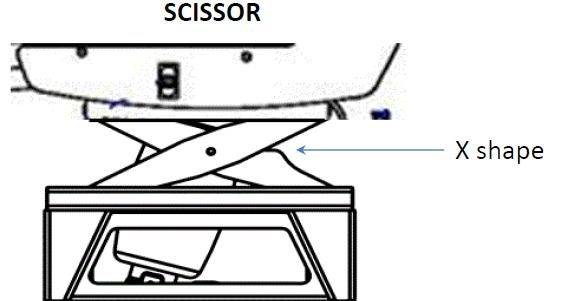

I have a suspended seat with a scissor mechanism like the following:

This seat is composed of coil spring and a hydraulic damper. My aim is to develop a multibody model of that seat. Actually, my model is quite complete, only the parameters of damper are missing (i.e. the damping coefficient with respect to its piston speed). I do not have any technical details about it, so I need to estimate it. I am thinking to use a system identification approach, that means, applying a known excitation to the seat, measure the displacement of the seat cushion and tune the model parameter so that the measured displacement will be reproduced. I do not have any rig so that I can easily apply a known excitation. I was thinking to excite the seat by applying an impulse (falling mass at a certain height) to the seat cushion. What do you think about this approach? Do you know an easier approach to get the damping curve of the damper?

This seat is composed of coil spring and a hydraulic damper. My aim is to develop a multibody model of that seat. Actually, my model is quite complete, only the parameters of damper are missing (i.e. the damping coefficient with respect to its piston speed). I do not have any technical details about it, so I need to estimate it. I am thinking to use a system identification approach, that means, applying a known excitation to the seat, measure the displacement of the seat cushion and tune the model parameter so that the measured displacement will be reproduced. I do not have any rig so that I can easily apply a known excitation. I was thinking to excite the seat by applying an impulse (falling mass at a certain height) to the seat cushion. What do you think about this approach? Do you know an easier approach to get the damping curve of the damper?

Thanks,

best regards

I have a suspended seat with a scissor mechanism like the following:

Thanks,

best regards