Juanda

Gold Member

- 439

- 145

- TL;DR

- Bernoulli equations result in exit speed being independent of the nozzle diameter which contradicts personal experiences. What am I missing?

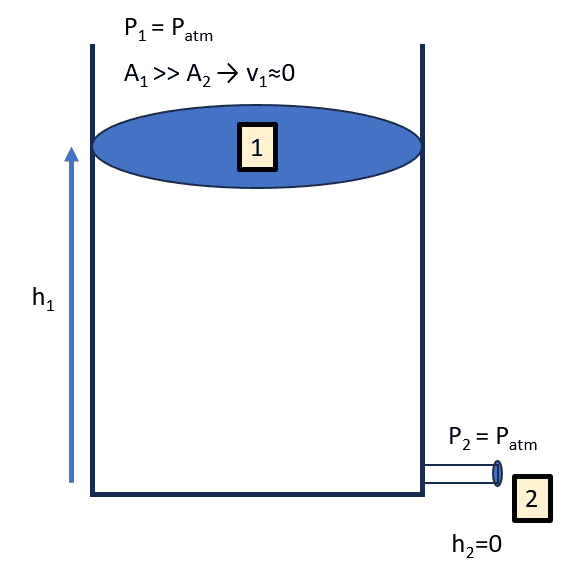

There is a classical example when teaching Bernoulli equations to get the exit velocity of a fluid leaving through the bottom of a tank. If we consider no energy is lost due to friction, the exit velocity turns out to be ##v=\sqrt {2gh}##. I'm having trouble processing the fact that exit speed is independent of nozzle diameter because it contradicts my real-world experience.

Let's assume an ideal scenario where there are no losses in pressure due to friction, water is incompressible and the area of the tank is MUCH greater than the area of exiting pipe. Then, Bernoulli can be applied in the following form.

##P_1+\rho gh_1+\frac{1}{2}\rho v_1^2=P_2+\rho gh_2+\frac{1}{2}\rho v_2^2\rightarrow v_2=\sqrt {2gh_1}##

According to that, no matter the diameter of the nozzle (as long as ##A_1>>A_2## and the time interval considered is not too long) I will get the same exit speed. I would expect that as I reduce the nozzle diameter, the exit speed should increase. At least, that's what my real-world experience tells me.

Am I missing something?

Is this due to the idealization of the problem? If losses due to friction and the nozzle were considered would the diameter of the nozzle affect the exit speed?

Let's assume an ideal scenario where there are no losses in pressure due to friction, water is incompressible and the area of the tank is MUCH greater than the area of exiting pipe. Then, Bernoulli can be applied in the following form.

##P_1+\rho gh_1+\frac{1}{2}\rho v_1^2=P_2+\rho gh_2+\frac{1}{2}\rho v_2^2\rightarrow v_2=\sqrt {2gh_1}##

According to that, no matter the diameter of the nozzle (as long as ##A_1>>A_2## and the time interval considered is not too long) I will get the same exit speed. I would expect that as I reduce the nozzle diameter, the exit speed should increase. At least, that's what my real-world experience tells me.

Am I missing something?

Is this due to the idealization of the problem? If losses due to friction and the nozzle were considered would the diameter of the nozzle affect the exit speed?

Last edited: