Smushiehippo

- 10

- 0

- Homework Statement

- Explain where the first point of failure is likely to originate, and why.

An analysis of the studies, do you think that they will be an accurate representation of what will happen in practice?

- Relevant Equations

- none

Hi

Im slightly stuck not sure what i put is ok.

FEA was used to carry out analysis on 3 structures and diagram results obtain (no data)

Explain where the first point of failure is likely to originate, and why.

An analysis of the studies, do you think that they will be an accurate representation of what will happen in practice?

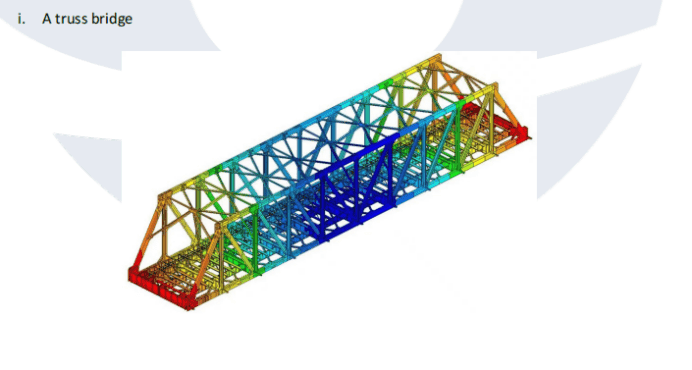

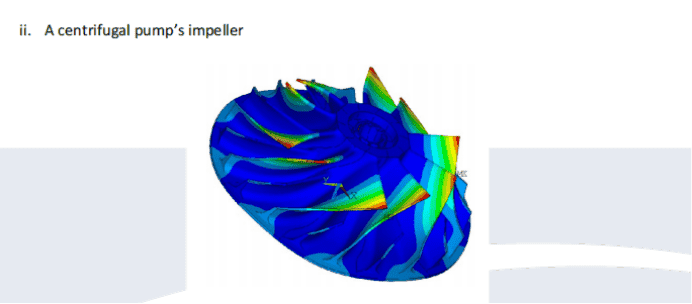

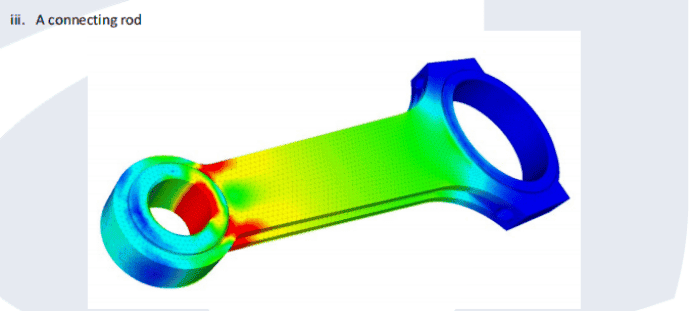

Red indicates high stress and blue indicates low stress

For the (i) there is high stress at both ends and low stress in center. I believe 1st point of failure would be at centre (blue area) and not indicated on diagram of high stress (red). Trusses support the bridge and take the majority of the load and stresses. Blue section centre of the bridge and where load and stress will be most concentrated. contentrated stresses and loading will likely fatigue in beam.

For the (ii) there is high stress at each blade and low stress at the base. I believe 1st point of failure would be at blade (red). Impeller blade are the thinest point on the structure. strength in this area is lowest compared to base. excess high vibration could lead to fatigue and first point of failure.

For the (iii) there is high close to the small end and low stress in big end. I believe 1st point of failure would be at small end (red). connecting rod under goes compression and tension in operation. high speed causing high rpm lead to stretching of the rod leading to failure.

Im stuck on comparing accurcy. I believe (i) is inaccurate but (ii and iii) are accurate. how do i compare accuracy with only pics and no data. im not 100% what each pic is showing, eg compression, tension, deformation.

Im slightly stuck not sure what i put is ok.

FEA was used to carry out analysis on 3 structures and diagram results obtain (no data)

Explain where the first point of failure is likely to originate, and why.

An analysis of the studies, do you think that they will be an accurate representation of what will happen in practice?

Red indicates high stress and blue indicates low stress

For the (i) there is high stress at both ends and low stress in center. I believe 1st point of failure would be at centre (blue area) and not indicated on diagram of high stress (red). Trusses support the bridge and take the majority of the load and stresses. Blue section centre of the bridge and where load and stress will be most concentrated. contentrated stresses and loading will likely fatigue in beam.

For the (ii) there is high stress at each blade and low stress at the base. I believe 1st point of failure would be at blade (red). Impeller blade are the thinest point on the structure. strength in this area is lowest compared to base. excess high vibration could lead to fatigue and first point of failure.

For the (iii) there is high close to the small end and low stress in big end. I believe 1st point of failure would be at small end (red). connecting rod under goes compression and tension in operation. high speed causing high rpm lead to stretching of the rod leading to failure.

Im stuck on comparing accurcy. I believe (i) is inaccurate but (ii and iii) are accurate. how do i compare accuracy with only pics and no data. im not 100% what each pic is showing, eg compression, tension, deformation.