Mahonroy

- 14

- 0

- TL;DR Summary

- I am experimenting with garden hose and pumps, to achieve furthest water spray distance. I hit a wall and am currently stuck on the problem.

Hello, I am trying to throw water the furthest distance possible from a garden hose and an inline water pump. The amount of water is not important - e.g. a tiny stream is perfectly fine, so long as it reachest a really far distance. I understand wind severely messes this up, so lets not worry about wind for now.

My goal is to reach a minimum of 100 feet, utilizing one pump is no problem, and utilizing 2 pumps in series only if absolutely necessary.

A quick overview:

My water pressure out of the garden hose is roughly 50psi with the end completely blocked off. Fully open I am getting about 5 gallons per minute of flow.

The pumps I have are 1.6HP, 1300GPH.

I tried a bunch of different "jet" style nozzles, and this one seemed to perform the best as far as distance is concerned. The hole is 3.7mm in diameter:

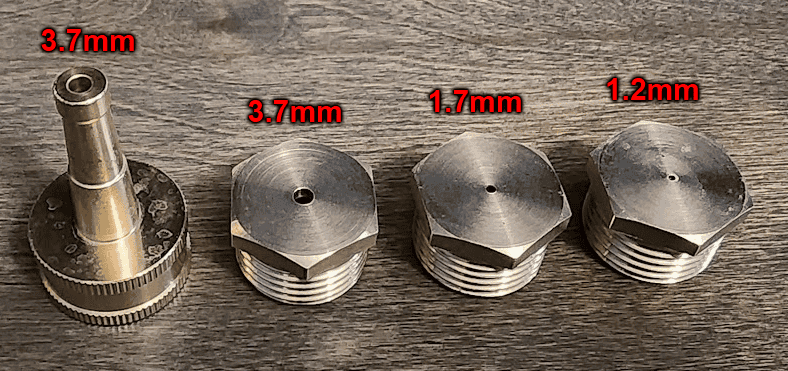

As a test, I drilled the same 3.7mm hole in a brass garden hose plug, and it performed pretty much exactly the same (to my surprise):

Initial testing using the above nozzles. I have a pressure gauge right before the nozzle:

Garden hose reads 50psi when closed at the nozzle. When fully open, pressure reads 0 psi and water shoots about 20 feet.

Using 1 pump, pressure reads 115psi when closed at the nozzle. When fully open, pressure reads 30-40psi, and water shoots about 65 feet.

Using 2 pumps in series, pressure reads 150psi when closed at the nozzle. When fully open, pressure reads about 100psi, and water shoots about 90 feet.

There is a decent amount of misting/spraying surrounding the stream - it sort of resembles those large sprinklers at parks and golf courses.

I decided to do some more testing with different diameter holes, just on the garden hose with no pump:

I mentioned above, the 3.7mm hole yielded a distance of about 20 feet. To my surprise, the 1.7mm hole performed the best, and gave a fairly steady stream (not much mist) and got 30 feet. Pressure guage read 20 psi right before the nozzle. I tried this same 1.7mm nozzle with a single pump, and the distance actually went down slightly to 25 feet, with a lot more water spray and mist. The pressure guage read 60psi. It looks like a lot more water volume is flowing out of the nozzle, but its less controlled.

The 1.2mm got about 25 feet with the garden hose (lots of spray/mist), and about 20 feet with the single pump (a lot more spray/mist). Pressure gauge read 80psi.

So now I am not sure which way to go with this. It seems more of a laminar flow is the way to get better distances, but if I achieve a nice stream at one pressure - as I increase pressure the stream is not so nice anymore - and in most cases it reduces the distance.

I considered attempting to build a liminar flow canister similar to "The King of Random" youtube video:

But he even mentioned that as he increased pressure it started to perform bad. So I am not confident that my canister would help things.

Another option is to just keep throwing pumps at the problem, as I am getting further and further distances with more pumps.... but each one draws 10 amps of current, so I won't even be able to put all of those on a single circuit. Ideally I want to accomplish this with a single pump.

Is there a way I can calculate this? E.g. mathematically arrive at some diameter hole at X pressure. Or some other type of nozzle design I should try?

Any help or advice is greatly appreciated, thanks!

My goal is to reach a minimum of 100 feet, utilizing one pump is no problem, and utilizing 2 pumps in series only if absolutely necessary.

A quick overview:

My water pressure out of the garden hose is roughly 50psi with the end completely blocked off. Fully open I am getting about 5 gallons per minute of flow.

The pumps I have are 1.6HP, 1300GPH.

I tried a bunch of different "jet" style nozzles, and this one seemed to perform the best as far as distance is concerned. The hole is 3.7mm in diameter:

As a test, I drilled the same 3.7mm hole in a brass garden hose plug, and it performed pretty much exactly the same (to my surprise):

Initial testing using the above nozzles. I have a pressure gauge right before the nozzle:

Garden hose reads 50psi when closed at the nozzle. When fully open, pressure reads 0 psi and water shoots about 20 feet.

Using 1 pump, pressure reads 115psi when closed at the nozzle. When fully open, pressure reads 30-40psi, and water shoots about 65 feet.

Using 2 pumps in series, pressure reads 150psi when closed at the nozzle. When fully open, pressure reads about 100psi, and water shoots about 90 feet.

There is a decent amount of misting/spraying surrounding the stream - it sort of resembles those large sprinklers at parks and golf courses.

I decided to do some more testing with different diameter holes, just on the garden hose with no pump:

I mentioned above, the 3.7mm hole yielded a distance of about 20 feet. To my surprise, the 1.7mm hole performed the best, and gave a fairly steady stream (not much mist) and got 30 feet. Pressure guage read 20 psi right before the nozzle. I tried this same 1.7mm nozzle with a single pump, and the distance actually went down slightly to 25 feet, with a lot more water spray and mist. The pressure guage read 60psi. It looks like a lot more water volume is flowing out of the nozzle, but its less controlled.

The 1.2mm got about 25 feet with the garden hose (lots of spray/mist), and about 20 feet with the single pump (a lot more spray/mist). Pressure gauge read 80psi.

So now I am not sure which way to go with this. It seems more of a laminar flow is the way to get better distances, but if I achieve a nice stream at one pressure - as I increase pressure the stream is not so nice anymore - and in most cases it reduces the distance.

I considered attempting to build a liminar flow canister similar to "The King of Random" youtube video:

But he even mentioned that as he increased pressure it started to perform bad. So I am not confident that my canister would help things.

Another option is to just keep throwing pumps at the problem, as I am getting further and further distances with more pumps.... but each one draws 10 amps of current, so I won't even be able to put all of those on a single circuit. Ideally I want to accomplish this with a single pump.

Is there a way I can calculate this? E.g. mathematically arrive at some diameter hole at X pressure. Or some other type of nozzle design I should try?

Any help or advice is greatly appreciated, thanks!

Last edited by a moderator: