- #1

DPress

- 1

- 0

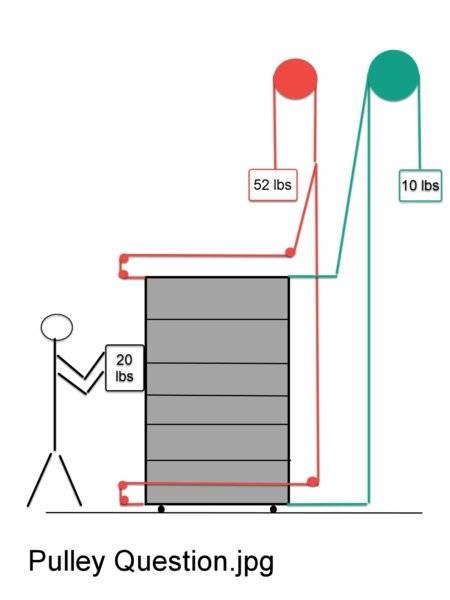

Something does not make sense. I have built a large bookcase on rolling wheels (on a concrete floor). I have connected it to wire rope and pulleys as shown in "Pulley Question.jpg". I always keep a 10 lb weight on each side so the lines do not go slack and fall off the pulleys.

I need to add an additional 42lbs to one side or another to get it to move.

Alternatively if I push the bookcase with a scale, the scale reads about 20lbs. (now with 10 lb weights on both upper wire ropes).

The only explanation I can think of is that the difference is caused by the delta between rolling and static friction that I am simply not seeing on the scale as I push it? But I thought there was none with the wheels under the bookcase? Could I have that much static friction in my pulley system?

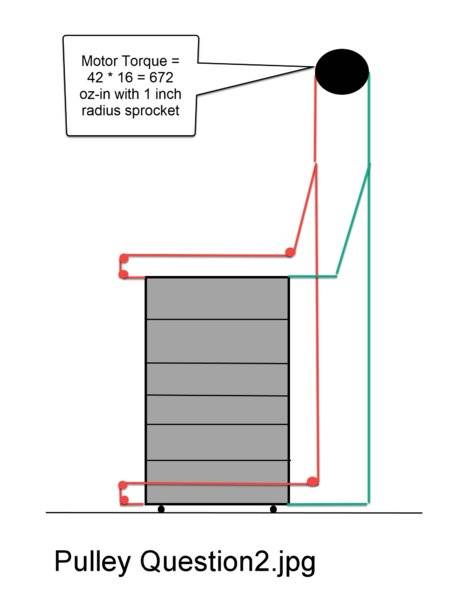

Assuming I have not made some gross error in my thinking, does this imply that I would need a motor capable of suppying 672 oz-in of torque (42 * 16) of torque, as shown in "Pulley Question2.jpg"? Note I will be using a 1" radius chain sprocket on the motor.

Finally, I would like to do this with a stepper motor so I can accelerate and decellerate smoothly. I think I will need a geared motor to get the Torque I need at the fairly low top speed required of 30 inches per second**

Thank you for your time in looking at this.** I want the bookcase to move 45 inches in 3 seconds for an average speed of 15 inches per second. So assuming constant acceleration and deceleration I would need a top speed of 30 inches per second - right?

I need to add an additional 42lbs to one side or another to get it to move.

Alternatively if I push the bookcase with a scale, the scale reads about 20lbs. (now with 10 lb weights on both upper wire ropes).

The only explanation I can think of is that the difference is caused by the delta between rolling and static friction that I am simply not seeing on the scale as I push it? But I thought there was none with the wheels under the bookcase? Could I have that much static friction in my pulley system?

Assuming I have not made some gross error in my thinking, does this imply that I would need a motor capable of suppying 672 oz-in of torque (42 * 16) of torque, as shown in "Pulley Question2.jpg"? Note I will be using a 1" radius chain sprocket on the motor.

Finally, I would like to do this with a stepper motor so I can accelerate and decellerate smoothly. I think I will need a geared motor to get the Torque I need at the fairly low top speed required of 30 inches per second**

Thank you for your time in looking at this.** I want the bookcase to move 45 inches in 3 seconds for an average speed of 15 inches per second. So assuming constant acceleration and deceleration I would need a top speed of 30 inches per second - right?