- #1

Jackolantern

- 28

- 4

Hello all,

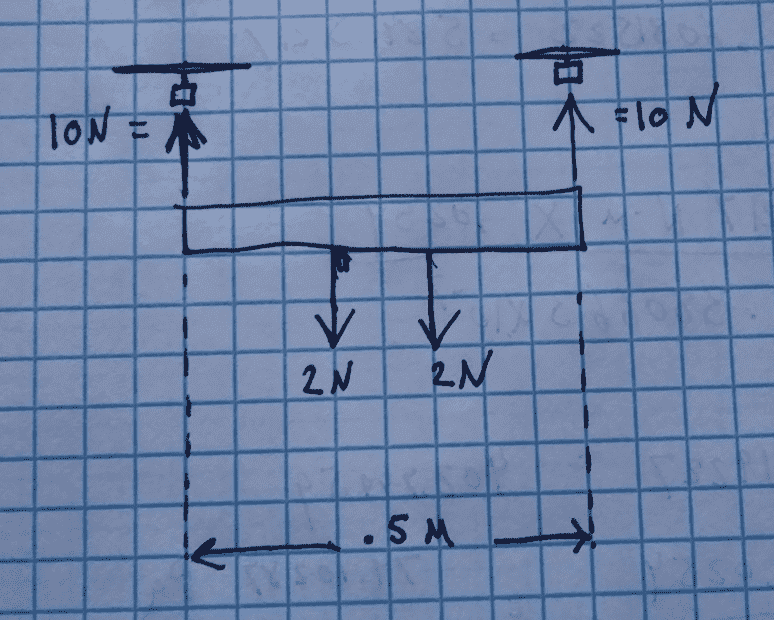

I'm trying to understand the maximum moment on a free beam. Consider a tail sitter drone that is simplified into being a beam with two motors fitted with propellers on the end of the beam (see the photo below), let the payload be estimated as two, 2 newton loads going downwards. If the drone is at rest, and its motors are suddenly turned to the highest thrust they can output (10 N), what is the maximum moment experienced on the beam and what is its location? Consider the weight of the beam and the motors to be zero.

Each square on the paper is equivalent to a length of 6.25 cm.

To solve this, I consider half of the beam to be a cantilever beam fixed at one end, the maximum moment then becomes:

Mnet = 10N x 0.25m - (2N x 0.0625m) = 2.375 N-m at the root of the imagined cantilever beam, and directly in the middle of the entire real beam.

My question is, is this correct? I just feel like something is wrong here since it is a free beam. Would things change at all if the motors revved up to 10 N slowly instead of instantaneously, and what if it gained velocity in the direction of the motor's thrust before the motors reached 10 N?

Any insight would BE MUCH APPRECIATED.

I'm trying to understand the maximum moment on a free beam. Consider a tail sitter drone that is simplified into being a beam with two motors fitted with propellers on the end of the beam (see the photo below), let the payload be estimated as two, 2 newton loads going downwards. If the drone is at rest, and its motors are suddenly turned to the highest thrust they can output (10 N), what is the maximum moment experienced on the beam and what is its location? Consider the weight of the beam and the motors to be zero.

Each square on the paper is equivalent to a length of 6.25 cm.

To solve this, I consider half of the beam to be a cantilever beam fixed at one end, the maximum moment then becomes:

Mnet = 10N x 0.25m - (2N x 0.0625m) = 2.375 N-m at the root of the imagined cantilever beam, and directly in the middle of the entire real beam.

My question is, is this correct? I just feel like something is wrong here since it is a free beam. Would things change at all if the motors revved up to 10 N slowly instead of instantaneously, and what if it gained velocity in the direction of the motor's thrust before the motors reached 10 N?

Any insight would BE MUCH APPRECIATED.