kunalv

- 29

- 1

- TL;DR Summary

- Designed & machined a gearbox with single input and double outputs at 90 degree to each other. Help needed with reducing the size

Hello,

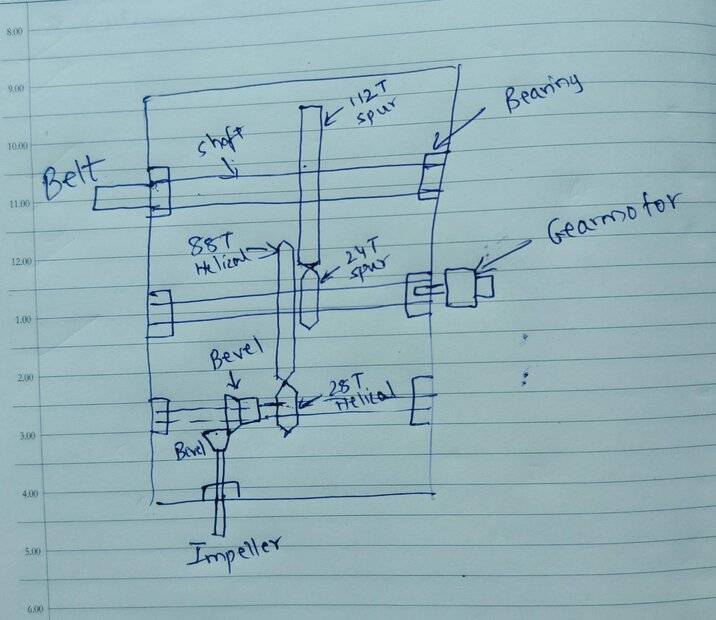

For a trial project (can't give details on what the project is at the moment sorry!), I have designed a gearbox that takes input from a DC gearmotor at 150RPM, and provides 2 outputs as per the following:

1. 32rpm in the same axis as the input. This drives the pulleys and the belt

2. 460rpm at right angle (vertically down). This drives an impeller in the water

Please see the layout as per this

The gearbox looks like this -

I have the following issues:

1. I have used 0.75 module gears, although I feel I can reduce the module and go for smaller gears. This will reduce the size of the gearbox & weight of the machine. Pls comment

2. Now the input gearmotor is connected to the 24Teeth Spur Gear in the middle of the gearbox. Can I re-design it to have the input gearmotor mounted near the top? See image below..

The input gearmotor will be the 50RPM one at the top driving the 75 Teeth Spur gear in this layout. I am going to use PWM to vary the speed of both outputs.

Comments/Suggestions/Corrections are welcome please. Thank you!

For a trial project (can't give details on what the project is at the moment sorry!), I have designed a gearbox that takes input from a DC gearmotor at 150RPM, and provides 2 outputs as per the following:

1. 32rpm in the same axis as the input. This drives the pulleys and the belt

2. 460rpm at right angle (vertically down). This drives an impeller in the water

Please see the layout as per this

The gearbox looks like this -

I have the following issues:

1. I have used 0.75 module gears, although I feel I can reduce the module and go for smaller gears. This will reduce the size of the gearbox & weight of the machine. Pls comment

2. Now the input gearmotor is connected to the 24Teeth Spur Gear in the middle of the gearbox. Can I re-design it to have the input gearmotor mounted near the top? See image below..

The input gearmotor will be the 50RPM one at the top driving the 75 Teeth Spur gear in this layout. I am going to use PWM to vary the speed of both outputs.

Comments/Suggestions/Corrections are welcome please. Thank you!