curtis73

- 6

- 0

The long story is, I'm building a powder coating oven out of an old steel cabinet. The process is to coat an item with powdered color, then heat it to about 400F to melt the coating on (in case you're not familiar with the process). There is more to it than that, but for the sake of this discussion, that's all we need to know. Skip to the end for the short story.

I'm going back and forth on using primarily radiant heat vs convection, but I wonder how much it will matter in the long run. I'm going to run some ideas past you and can you "grade my essay?"

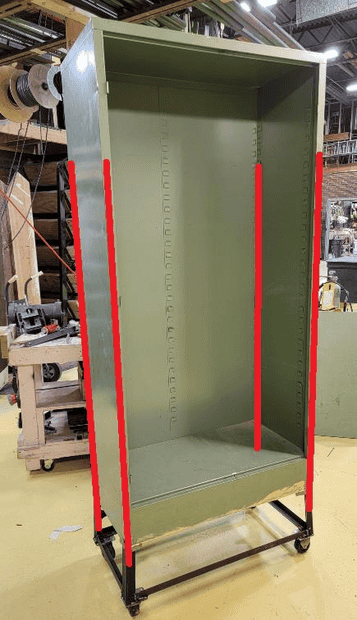

First, the cabinet in question:

The bottom is yet to be skinned, and obviously the doors are off. The whole thing will be insulated inside with a 1" rigid fiberglass board, and the outside will have 4" of rockwool or fiberglass batt insulation. I've drawn red lines in the corners which was my first idea - using four, 4' long IR halogen heating elements. The idea was to heat the part more than the air which should be more efficient as opposed to heating the very poorly-conducting air and relying on convection... which was my second idea. Using traditional household oven elements near the bottom of the sides to heat the air to convection-heat the parts.

My real thought here was that using a radiant heat source would be more efficient - that is to say, I could achieve my target curing temperature on the coated part with fewer BTUs or watts expended, but before I can start mathing out how much output I need, I need to know just how much (relatively speaking) the difference will be between convection vs radiation.

For example, here are some heating elements I've been considering.

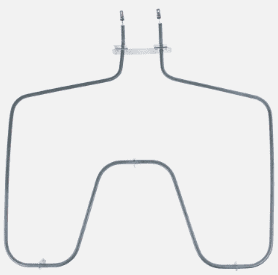

Traditional electric oven heating elements (primarily convection):

Traditional LPG grill burners (primarily convection):

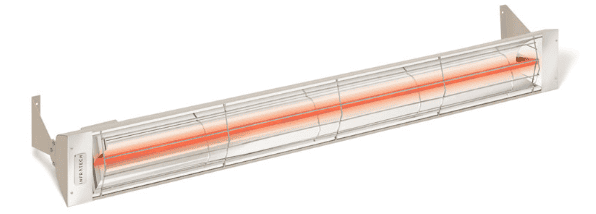

IR-emitting halogen elements (primarily radiant):

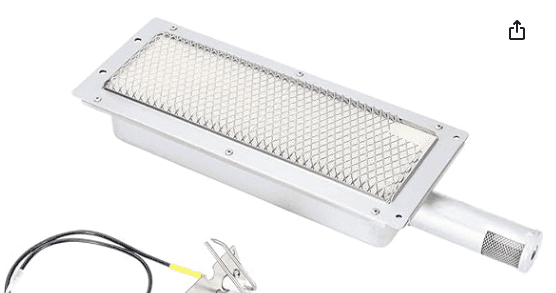

LPG catalyst radiant heaters (primarily radiant):

My real question is this: All of the above elements will produce both radiant and convective heat.... but in what ratios? Is the radiant halogen 90% radiant and 10% convecting, or 60/40? What about the oven element? I know it will offer some radiant energy, but how much?

The reason I need to know is because there is a requirement to pretty accurately control the heat of the entire piece being coated. I can't have one end reaching 450 degrees F while the other end is only 350.

My brain is telling me that I either need to do a whole bunch of smaller IR so I can bathe the whole part, or a few large hot things so I can heat the AIR to my temperature and (with the help of air circulation) make sure all of the air in contact with the part is doing the job of evenly heating. But I don't want to mess up and put a bunch of convective heaters in the bottom only to find out that their radiant heat is greater than anticipated and thereby scorching the bottom of the parts

If any of that made sense, great. If not, the short story is:

Let's say you needed to use that above cabinet to evenly heat something to 400 degrees. How would you do it?

I'm going back and forth on using primarily radiant heat vs convection, but I wonder how much it will matter in the long run. I'm going to run some ideas past you and can you "grade my essay?"

First, the cabinet in question:

The bottom is yet to be skinned, and obviously the doors are off. The whole thing will be insulated inside with a 1" rigid fiberglass board, and the outside will have 4" of rockwool or fiberglass batt insulation. I've drawn red lines in the corners which was my first idea - using four, 4' long IR halogen heating elements. The idea was to heat the part more than the air which should be more efficient as opposed to heating the very poorly-conducting air and relying on convection... which was my second idea. Using traditional household oven elements near the bottom of the sides to heat the air to convection-heat the parts.

My real thought here was that using a radiant heat source would be more efficient - that is to say, I could achieve my target curing temperature on the coated part with fewer BTUs or watts expended, but before I can start mathing out how much output I need, I need to know just how much (relatively speaking) the difference will be between convection vs radiation.

For example, here are some heating elements I've been considering.

Traditional electric oven heating elements (primarily convection):

Traditional LPG grill burners (primarily convection):

IR-emitting halogen elements (primarily radiant):

LPG catalyst radiant heaters (primarily radiant):

My real question is this: All of the above elements will produce both radiant and convective heat.... but in what ratios? Is the radiant halogen 90% radiant and 10% convecting, or 60/40? What about the oven element? I know it will offer some radiant energy, but how much?

The reason I need to know is because there is a requirement to pretty accurately control the heat of the entire piece being coated. I can't have one end reaching 450 degrees F while the other end is only 350.

My brain is telling me that I either need to do a whole bunch of smaller IR so I can bathe the whole part, or a few large hot things so I can heat the AIR to my temperature and (with the help of air circulation) make sure all of the air in contact with the part is doing the job of evenly heating. But I don't want to mess up and put a bunch of convective heaters in the bottom only to find out that their radiant heat is greater than anticipated and thereby scorching the bottom of the parts

If any of that made sense, great. If not, the short story is:

Let's say you needed to use that above cabinet to evenly heat something to 400 degrees. How would you do it?