- #1

Goldscuttle

- 4

- 0

Hi,

I'd like to build a homopolar generator. Since generating magnetic fields of uniform density of any useful size is very tricky to do with off the shelf permanent magnets (I've tried!) I had the idea to use DC solenoids instead. But with a rotating helical plate in place of the cylindrical solenoid core. (basically replace the iron core with a screw with wide, thick threads) In either case, the voids will be packed with a paramagnetic material in order to encourage the fields to flow between the planar surfaces. The core will be made or allowed to spin while the coil remains stationary.

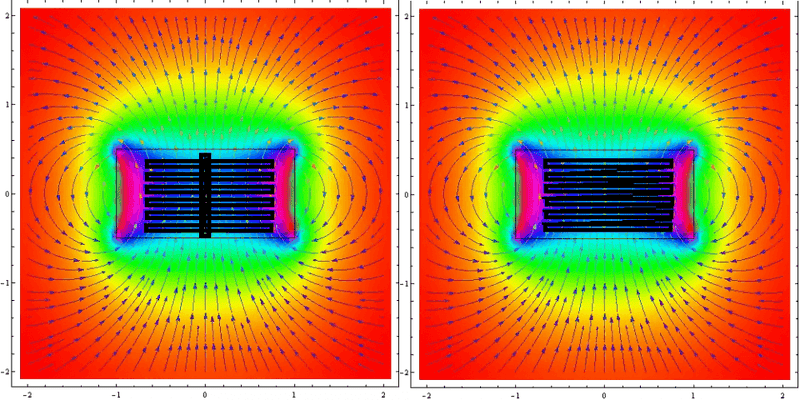

Below are two diagrams that I hope clarify what I'm describing. The one on the left is the more conventional plate rotating while cutting through magnetic fields, there are just more of them. The helical one on the right I haven't ever seen but it occurred to me as a possible simplification. I have several related questions about this theoretical contraption before I plunk down a few bucks on a prototype.

Could a shaft made of stacked rings (such as copper washers threaded onto a metal spindle) be expected to perform identically to a bona fide helix where the surface between ends is continuous?

ie. For the stacked rings would the currents add like battery cells in series or would they cancel out?

And, since the helical core has no center spindle except maybe for mechanical support, would the voltage difference simply be measured from any inner edge to the outer edge of the same elevation? OR is the voltage gradient the same as the stacked ring config? (center to edge)

TIA for any improvements/pitfalls that you can point out.

I'd like to build a homopolar generator. Since generating magnetic fields of uniform density of any useful size is very tricky to do with off the shelf permanent magnets (I've tried!) I had the idea to use DC solenoids instead. But with a rotating helical plate in place of the cylindrical solenoid core. (basically replace the iron core with a screw with wide, thick threads) In either case, the voids will be packed with a paramagnetic material in order to encourage the fields to flow between the planar surfaces. The core will be made or allowed to spin while the coil remains stationary.

Below are two diagrams that I hope clarify what I'm describing. The one on the left is the more conventional plate rotating while cutting through magnetic fields, there are just more of them. The helical one on the right I haven't ever seen but it occurred to me as a possible simplification. I have several related questions about this theoretical contraption before I plunk down a few bucks on a prototype.

Could a shaft made of stacked rings (such as copper washers threaded onto a metal spindle) be expected to perform identically to a bona fide helix where the surface between ends is continuous?

ie. For the stacked rings would the currents add like battery cells in series or would they cancel out?

And, since the helical core has no center spindle except maybe for mechanical support, would the voltage difference simply be measured from any inner edge to the outer edge of the same elevation? OR is the voltage gradient the same as the stacked ring config? (center to edge)

TIA for any improvements/pitfalls that you can point out.