YoshiMoshi

- 233

- 10

- TL;DR Summary

- How much should I adjust torque when using anti-seize?

Rust belt fasteners on cars that have been in use for about 20 years, sometimes seize up and snap inside of their holes. I would like to avoid the frustration going forward of this happening by using anti-seize. How much should I adjust torque specifications by when using anti-seize? Looking online, I can't seem to really get a clear answer. Everybody seems to have their own opinions on this matter. A common recommendation online is to reduce torque by about 25 %. Seems kind of scary to use anti-seize, if you can't determine how you should adjust the torque. It would seem to be pretty much useless. So I would like to figure it out.

This is for Toyota fasteners that fit into one of three categories. Toyota fasteners have their own specifications. Their head markings are not ones that you can find at hardware stores or auto parts stores.

T = K D P

If:

T_Dry = K_Dry D P

T_Anti-Seize = K_Anti-Seize D P

Then:

T_Anti-Seize / T_Dry = (K_Anti-Seize D P) / (K_Dry D P)

T_Anti-Seize / T_Dry = K_Anti-Seize / K_Dry

Finally:

T_Anti-Seize = (T_Dry K_Anti-Seize) / K_Dry

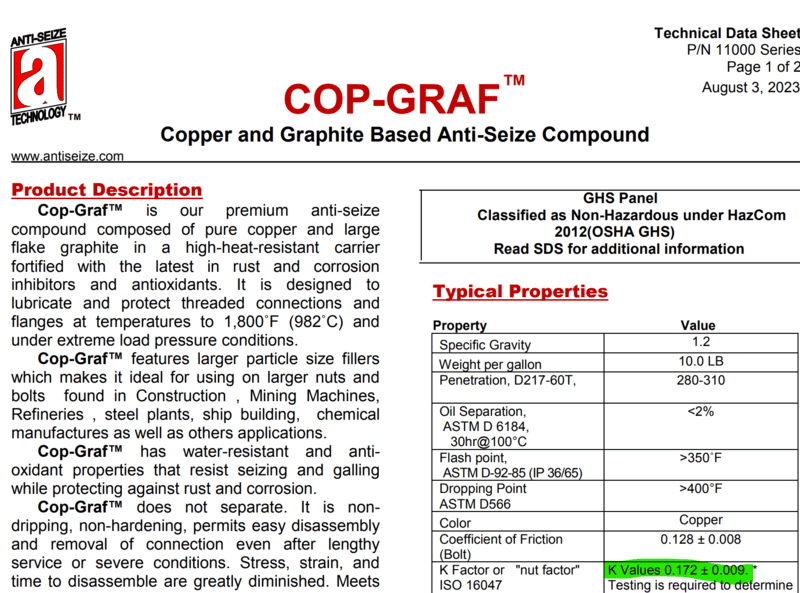

Looking online, the K value is not typically specified by anti-seize manufactures. However I did find one specified value, https://www.antiseize.com/Content/Images/techdata/td11000.pdf. The Anti Seize Technology company makes a copper and graphite anti-seize compound whose K value is "0.172 +/- 0.009" in accordance with ISO 16047.

Assuming slightly over torquing a fastener would be better than slightly under torquing the fastener, I would go with the 0.172 + 0.009 value or 0.181.

Looking online at some websites, it seems like 0.2 is a good estimate for dry torque, non-lubricated fasteners. If this was the case, then I would reduce my torque by 10 %, when using Anti-Seize Technology COP-GRAF, to achieve the same clamp load as an unlubricated bolt.

Another common anti-seize manufacturer is Permatex. I couldn't find the K factor on the datasheets for their products, but I think they would likely give it to me if I asked (maybe).

Now my question becomes, is 0.2 a good assumption to make for non lubricated bolts? What value should I be using instead if not?

This is for Toyota fasteners that fit into one of three categories. Toyota fasteners have their own specifications. Their head markings are not ones that you can find at hardware stores or auto parts stores.

- Carbon steel bolt and alloy steel bolt

- Non heat treated type high strength bolt

- Boron steel bolt

T = K D P

- The desired clamp load, P, is not known by me as the end user.

- However, the ideal specified torque, T, for nearly all bolts for my vehicle is specified by the service information.

- D can be measured and is the diameter of the bolt

- The K value that was used while determining the torque specification is unknown to me as the end user. However, looking online, most torque specifications assume a clean bolt that is not lubricated. If the torque specification is made assuming the bolt is lubricated before assembly, than the service information would likely specify to apply a specific lubricant on the threads before assembly.

If:

T_Dry = K_Dry D P

T_Anti-Seize = K_Anti-Seize D P

Then:

T_Anti-Seize / T_Dry = (K_Anti-Seize D P) / (K_Dry D P)

T_Anti-Seize / T_Dry = K_Anti-Seize / K_Dry

Finally:

T_Anti-Seize = (T_Dry K_Anti-Seize) / K_Dry

Looking online, the K value is not typically specified by anti-seize manufactures. However I did find one specified value, https://www.antiseize.com/Content/Images/techdata/td11000.pdf. The Anti Seize Technology company makes a copper and graphite anti-seize compound whose K value is "0.172 +/- 0.009" in accordance with ISO 16047.

Assuming slightly over torquing a fastener would be better than slightly under torquing the fastener, I would go with the 0.172 + 0.009 value or 0.181.

Looking online at some websites, it seems like 0.2 is a good estimate for dry torque, non-lubricated fasteners. If this was the case, then I would reduce my torque by 10 %, when using Anti-Seize Technology COP-GRAF, to achieve the same clamp load as an unlubricated bolt.

Another common anti-seize manufacturer is Permatex. I couldn't find the K factor on the datasheets for their products, but I think they would likely give it to me if I asked (maybe).

Now my question becomes, is 0.2 a good assumption to make for non lubricated bolts? What value should I be using instead if not?

Last edited: