- #1

xiv_wolf

- 7

- 0

Good day everyone!

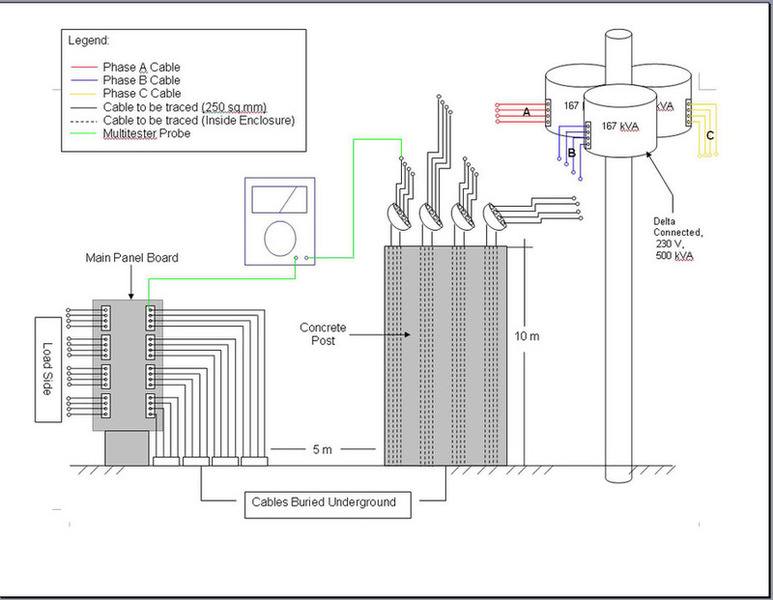

I would like to ask if it's ok to use a digital or analog multi-tester in testing a 15 meters, 250 sq.mm cable? We are tracing buried cables from the main circuit breaker to the concrete post. We are connected to Delta X'mer, 230 V, 4 wire w/ ground System. The x'mer will not be connected to the system while testing. I've attached the schematic diagram of the proposed method of testing. I appreciate any suggestions/recommendations. Thank you very much.

I would like to ask if it's ok to use a digital or analog multi-tester in testing a 15 meters, 250 sq.mm cable? We are tracing buried cables from the main circuit breaker to the concrete post. We are connected to Delta X'mer, 230 V, 4 wire w/ ground System. The x'mer will not be connected to the system while testing. I've attached the schematic diagram of the proposed method of testing. I appreciate any suggestions/recommendations. Thank you very much.