Oleg

- 9

- 0

- TL;DR Summary

- Friction at bearings depends on the properties of the bearings themselves, but how can I estimate the "extra friction" under the load? Is there any formula or rule of thumb?

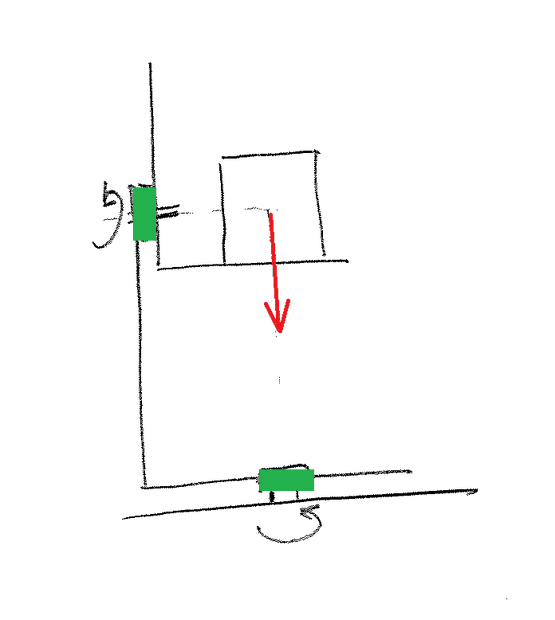

I'm willing to build a motorized gimbal head for my camera (something like this: https://www.amazon.com/dp/B01JN5D40A/?tag=pfamazon01-20).

If my understanding is correct, given that camera will be well balanced on the platform, the motors would not need to hold the load and only should be strong enough to overcome the static friction of the bearings. Obviously, it will depend on the properties of the bearings themselves, but how can I estimate the "extra friction" under the load? Is there any formula or rule of thumb?

If my understanding is correct, given that camera will be well balanced on the platform, the motors would not need to hold the load and only should be strong enough to overcome the static friction of the bearings. Obviously, it will depend on the properties of the bearings themselves, but how can I estimate the "extra friction" under the load? Is there any formula or rule of thumb?