- #1

omarmorocci

- 47

- 0

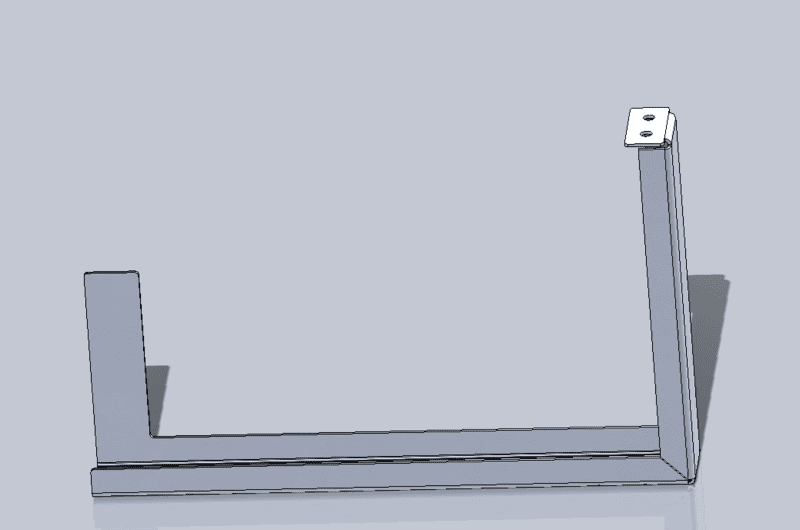

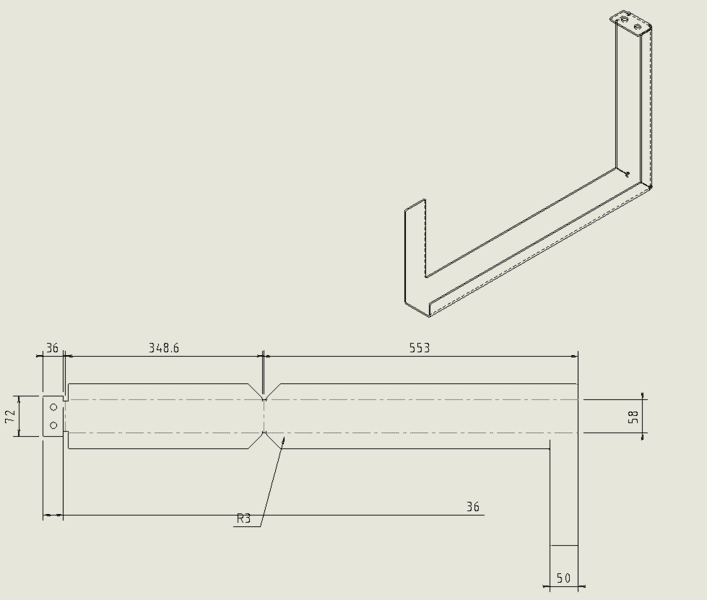

I would like to produce the 3mm thick sheet metal steel part shown bellow but I have a few questions.

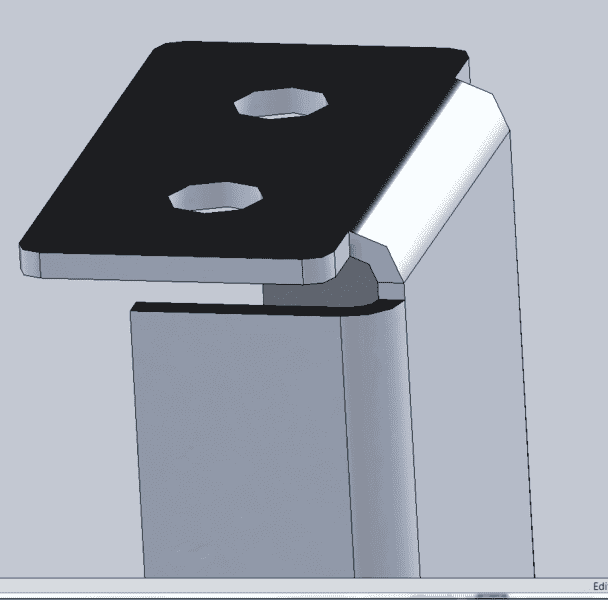

I have my doubts about the whether the bending of the top right part (with the holes) will work. The 5 mm spacing has to be there as the tool will be inserted into a 3 mm surface

Feel free to add any other comments

I have my doubts about the whether the bending of the top right part (with the holes) will work. The 5 mm spacing has to be there as the tool will be inserted into a 3 mm surface

Feel free to add any other comments