Vatech

- 53

- 7

- TL;DR Summary

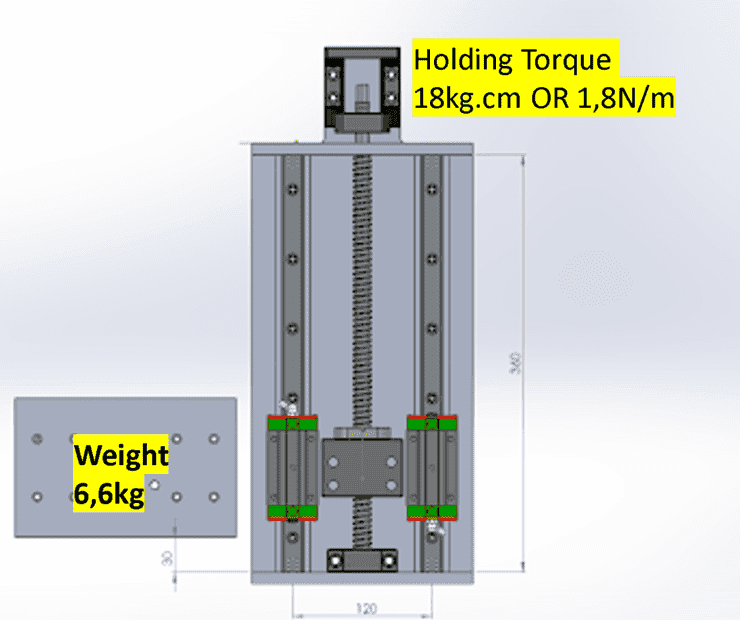

- it is needed to select stepper motor for a Z-axis application with Ballscrew.

we suppose as knowing data that the z axis is verstical and the load is 6.6kg.

I build a Z-axis (not the one displayed on image). The weight of the Buildplatform is 2.29kg and is going to be used on a MSLA printer, so the weight might get increased 1kg additionally, so 3.29kg. The problem is that when detached from the printed model from Fep film there is a resistive force, this needs tools and test to be calculated so this is unknown data for the time.

That’s why i would like to be able to lift double the weight , meaning 6.6kg.

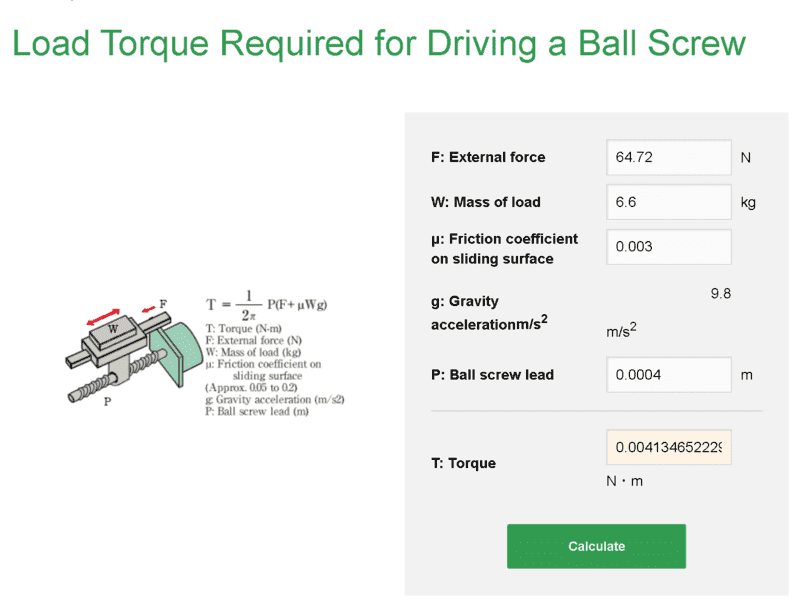

The ball screw is a SFU1204 , meaning 4mm travel per full rotation. Friction

I sourced experimental a stepper that has 1.8N holding torque, but how could i calculated the minimum Holding torque of the stepper motor needed to lift up the platform?

That’s why i would like to be able to lift double the weight , meaning 6.6kg.

The ball screw is a SFU1204 , meaning 4mm travel per full rotation. Friction

I sourced experimental a stepper that has 1.8N holding torque, but how could i calculated the minimum Holding torque of the stepper motor needed to lift up the platform?