MMImpel

- 7

- 3

- TL;DR Summary

- Help understanding hydrocyclones and a simple calculation using an empirical equation by Bradley

Hello,

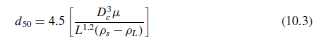

I want to see if hydrocyclones can be used in a application, where we have small metall particles that we want to extract from a closed loop water system. I found a book "Chemical Engineering Design" written by Richardson, where there are some equations given that makes it possible to calculate the effectiveness of the hydrocyclone dependent on the hydrocyclones and the water flow properties. I have used eq (10.3)

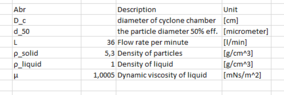

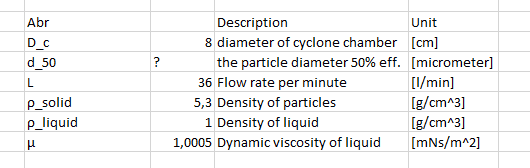

The following in-data are used

This gives me a value for the d_50 = 7,3 micrometer.

Firstly; what does this actually mean, will the hydrocyclone capture 50 % of the particles of the d_50 size what about if they are larger or smaller? Is it possible to determine how effective the hydrocyclone will be if the particles for instance have a d = 200 micrometers ?

I want to see if hydrocyclones can be used in a application, where we have small metall particles that we want to extract from a closed loop water system. I found a book "Chemical Engineering Design" written by Richardson, where there are some equations given that makes it possible to calculate the effectiveness of the hydrocyclone dependent on the hydrocyclones and the water flow properties. I have used eq (10.3)

The following in-data are used

This gives me a value for the d_50 = 7,3 micrometer.

Firstly; what does this actually mean, will the hydrocyclone capture 50 % of the particles of the d_50 size what about if they are larger or smaller? Is it possible to determine how effective the hydrocyclone will be if the particles for instance have a d = 200 micrometers ?