Hauzen

- 13

- 4

Hi!

I have a loss head question.

There is a difficulty in understanding the hydrodynamic loss head concept.

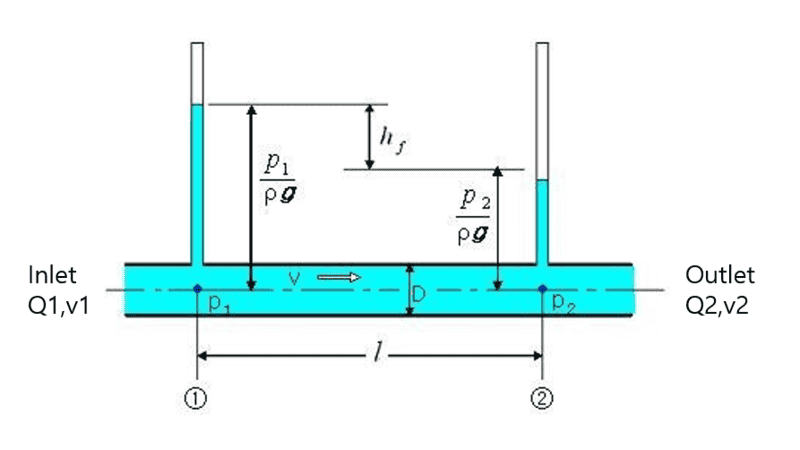

Assuming that there is a one-sided tube with incompressibility, visibility, tube friction coefficient and cross-sectional area A..

There is friction in the loss head formula, but is the flow rate and flow rate of the Inlet and Oulets the same?

I know that continuous equations are useful when there is no friction.

I don't understand that there is friction, but the flow rate of the Oulet does not decrease. And in the loss head, it is stated that v is the average velocity, but is it the v of the inlet? Is it the v of the outlet?

I don't understand the concept exactly.

I have a loss head question.

There is a difficulty in understanding the hydrodynamic loss head concept.

Assuming that there is a one-sided tube with incompressibility, visibility, tube friction coefficient and cross-sectional area A..

There is friction in the loss head formula, but is the flow rate and flow rate of the Inlet and Oulets the same?

I know that continuous equations are useful when there is no friction.

I don't understand that there is friction, but the flow rate of the Oulet does not decrease. And in the loss head, it is stated that v is the average velocity, but is it the v of the inlet? Is it the v of the outlet?

I don't understand the concept exactly.

Last edited by a moderator: