- #1

Melon

- 8

- 2

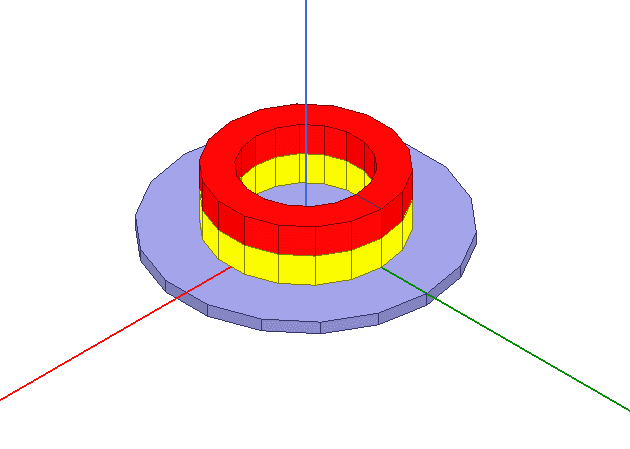

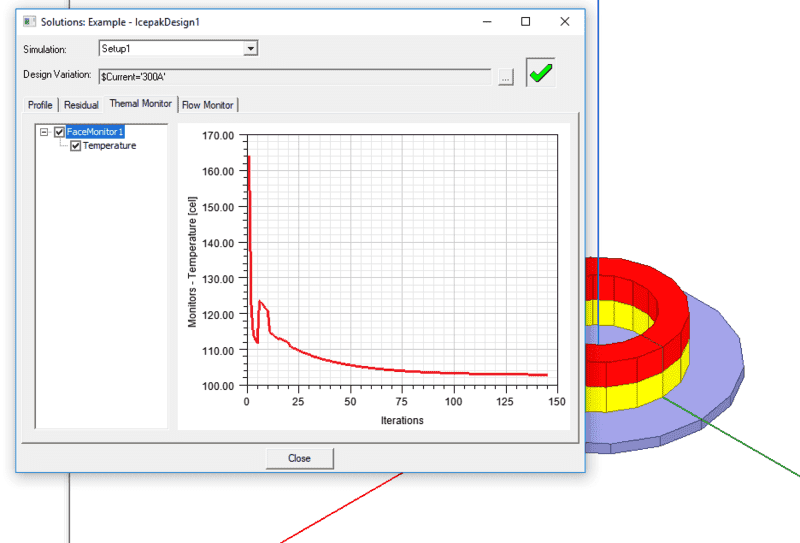

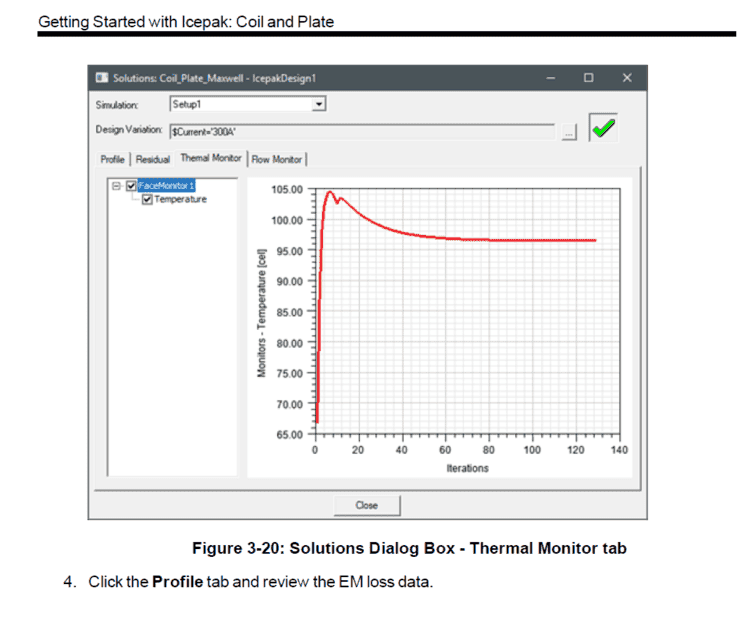

Hi Guys, I am doing a Maxwell&Icepak simulation according to the Icepak tutorial. But I get different result with the tutorial (seems as upside-down). Could you help raise some advice for this situation? Thanks!