jim hardy

Science Advisor

Homework Helper

Dearly Missed

- 9,832

- 4,898

[QUOTE="Jimmy Lalani, post: 5825807, member: 628145"T]he turns ratio =Vp/Vs= 230/24=9.5833.[/QUOTE]

Published numbers are for operation at rated load. They include voltage drop across Rp Xp Rs and Xs.

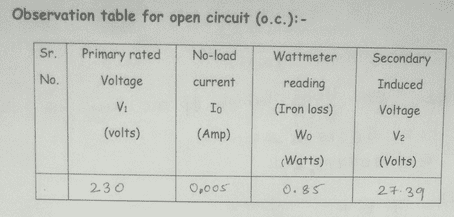

Turns ratio looks to me more like 230 / 27.39 = 8.397

That's why you run open circuit test, to eliminate or at least minimize the voltage drop across Rp Xp Rs and Xs

@Jimmy Lalani Try your calculations using observed turns ratio at open circuit

because that is when voltage drops across those impedances are negligible.. You'll come a lot closer to the actual turns ratio.

Published numbers are for operation at rated load. They include voltage drop across Rp Xp Rs and Xs.

Turns ratio looks to me more like 230 / 27.39 = 8.397

That's why you run open circuit test, to eliminate or at least minimize the voltage drop across Rp Xp Rs and Xs

@Jimmy Lalani Try your calculations using observed turns ratio at open circuit

because that is when voltage drops across those impedances are negligible.. You'll come a lot closer to the actual turns ratio.

Last edited: