yonese

- 15

- 1

- Homework Statement

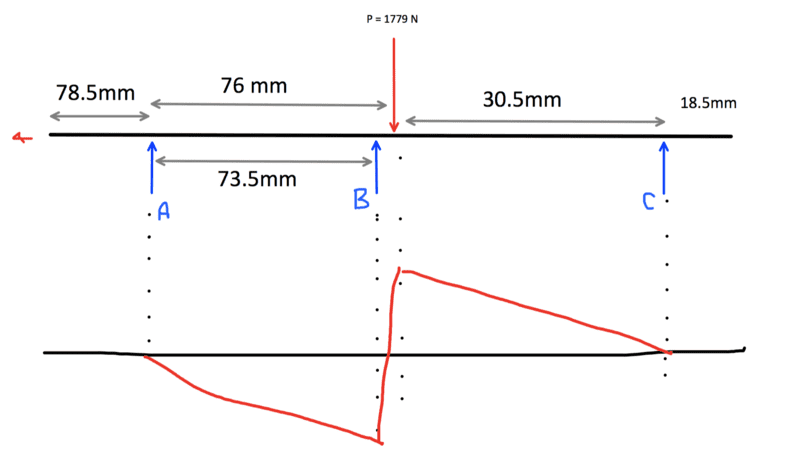

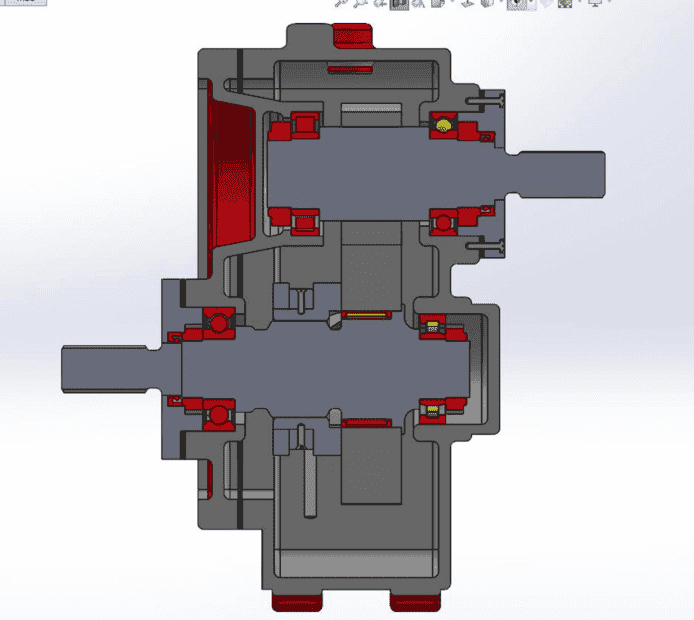

- I'm trying to solve for this intederminate beam for an output shaft for a gearbox I'm designing. I have 3 bearings (1 deep groove, 1 needle and 1 cylindrical) and I have assumed that axial load is negligible.

- Relevant Equations

- P = A+B+C

I have drawn the bending moment diagram to try to help me determine the moment, but I am certain my values are wrong. I have included a picture of my gearbox design, where the bottom shaft is what I'm trying to calculate. I've been able to calculate the top shaft moments and reaction forces with no problem. (Bending moment = 30.63 Nm, ball bearing = 850.8 N, roller bearing = 928.2N, Torque = 55.2 Nm)

For the bottom shaft, I am given that the torque is 107.8 Nm and I managed to get moment = 2.98 Nm, which just doesn't seem likely. My calculated reaction forces for the bearings are

Ball = 17 N

Needle = 1700 N

Roller = 98 N

It doesn't seem likely that the needle bearing would take so much of the load, considering the magnitude of my previous answers.

Is there a second load that I am missing? Or prehaps I should be taking the shaft and gear as a UDL?

For the bottom shaft, I am given that the torque is 107.8 Nm and I managed to get moment = 2.98 Nm, which just doesn't seem likely. My calculated reaction forces for the bearings are

Ball = 17 N

Needle = 1700 N

Roller = 98 N

It doesn't seem likely that the needle bearing would take so much of the load, considering the magnitude of my previous answers.

Is there a second load that I am missing? Or prehaps I should be taking the shaft and gear as a UDL?