kazx9r

- 49

- 4

- TL;DR Summary

- I was curious about what would happen if you take a jack hammer on a unsprung suspension.

Hello all, I wanted to know what would happen if I put a jack hammer system on the unsprung part of the suspension, I posted this on the engineering forum but couldn't get a complete answer.

https://www.eng-tips.com/viewthread.cfm?qid=512117

Basically the argument was if the reaction would react on the chassis in the same amount of load a jackhammer impacts an object .

Taking the main points from before,

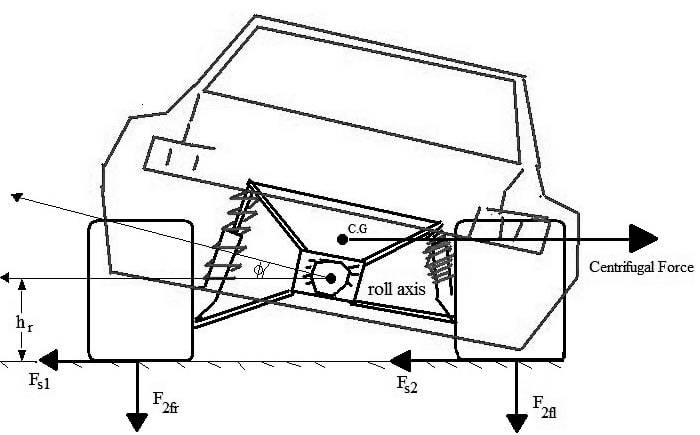

We're talking about a vehicle on a smooth surface, taking a turn, no bumps, the turn lasts less than a second or that the amount I need additional load on the inside tire is less than a second and I want to know the static force if you take a jack hammer type of machine to the unsprung part of the vehicle. I only need it for a split second while I'm either losing grip or making a turn. An illustration:

Would it create any kind of load on the tire patch? And would the reaction load just act upon the chassis because obviously the jack hammer is mounted to the car (could be on the unsprung part or chassis)? How to calculate the static load of a jack hammer?

Would it create any kind of load on the tire patch? And would the reaction load just act upon the chassis because obviously the jack hammer is mounted to the car (could be on the unsprung part or chassis)? How to calculate the static load of a jack hammer?

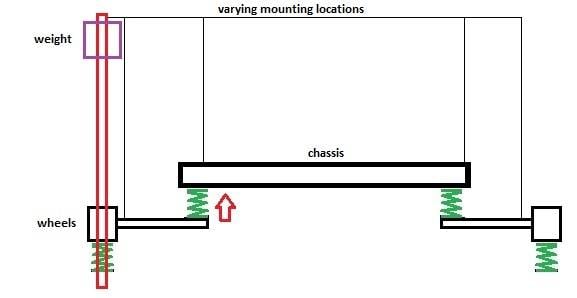

A simple experiment I ran (not sure if it's correct), I took a heavy weight and varied the location where I want to mount my so called jack hammer, basically right near the unsprung part of the suspension seemed the best.

What I noticed the rebound of only 25%, so basically the chassis moved up.

Some topics that were similar that I looked at:

https://physics.stackexchange.com/questions/175956...

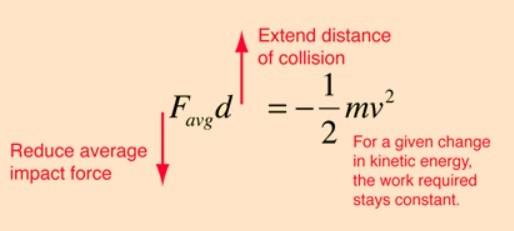

"For example, if a 5 pound hammer is swung at 50 feet per second, then the kinetic energy of the hammer is 5 * 50 * 50 / 64.32 = 194 foot pounds. If this then compresses a forging by 1/8 of an inch, then neglecting rebound, then it is about 194 * 96 or about 18,600 pounds of force on average. This is because 1/8" = 1/96th of a foot, and the average force is foot pounds / feet over which the force acts."

https://www.physicsforums.com/threads/linear-impul...

"During Operation the jack hammer develops on the concrete surface develops a force @ t=0 f=0, @ t=.2, F=90, @ t=.4, F=0. Graph looks like a triangle To achieve this the 2lb spike S, is fired from rest into the surface @ 200ft/s. Determine the speed of the spike just after rebounding"

Initial velocity: 60.96 m/s

Final rebound velocity:

Return Momentum = RP RP = mv = -24.799 = .907v therefore v = -27.341 m/s

Not sure how correct the above is, but I wanted to post what I looked at, it appears the rebound has far less velocity and given what I'm asking, it should transfer less force to the chassis or does it?

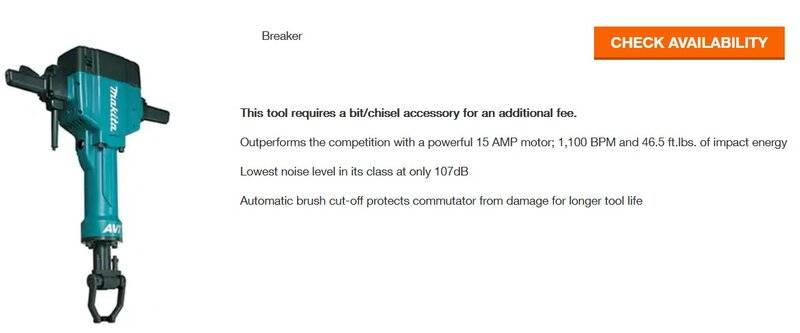

A typical jack hammer from Home Depot, it has a energy rating 46.5ft-lbs, not max impact load, so how do I calculate it or come close to finding static load?

Lets say a tire compresses .25" from the impact (or .0208 ft or 1/48th of a foot), so static load is 46.5ft-lbs X 48 = 2232 lbs per blow?

Would the reaction on the chassis also be this load? or would it be less or more? If less, why is it less?

Is this the correct formula? I don't think i have enough know values to find the reaction load on the chassis, can anyone help?

Sorry for the long post.

https://www.eng-tips.com/viewthread.cfm?qid=512117

Basically the argument was if the reaction would react on the chassis in the same amount of load a jackhammer impacts an object .

Taking the main points from before,

We're talking about a vehicle on a smooth surface, taking a turn, no bumps, the turn lasts less than a second or that the amount I need additional load on the inside tire is less than a second and I want to know the static force if you take a jack hammer type of machine to the unsprung part of the vehicle. I only need it for a split second while I'm either losing grip or making a turn. An illustration:

A simple experiment I ran (not sure if it's correct), I took a heavy weight and varied the location where I want to mount my so called jack hammer, basically right near the unsprung part of the suspension seemed the best.

What I noticed the rebound of only 25%, so basically the chassis moved up.

Some topics that were similar that I looked at:

https://physics.stackexchange.com/questions/175956...

"For example, if a 5 pound hammer is swung at 50 feet per second, then the kinetic energy of the hammer is 5 * 50 * 50 / 64.32 = 194 foot pounds. If this then compresses a forging by 1/8 of an inch, then neglecting rebound, then it is about 194 * 96 or about 18,600 pounds of force on average. This is because 1/8" = 1/96th of a foot, and the average force is foot pounds / feet over which the force acts."

https://www.physicsforums.com/threads/linear-impul...

"During Operation the jack hammer develops on the concrete surface develops a force @ t=0 f=0, @ t=.2, F=90, @ t=.4, F=0. Graph looks like a triangle To achieve this the 2lb spike S, is fired from rest into the surface @ 200ft/s. Determine the speed of the spike just after rebounding"

Initial velocity: 60.96 m/s

Final rebound velocity:

Return Momentum = RP RP = mv = -24.799 = .907v therefore v = -27.341 m/s

Not sure how correct the above is, but I wanted to post what I looked at, it appears the rebound has far less velocity and given what I'm asking, it should transfer less force to the chassis or does it?

A typical jack hammer from Home Depot, it has a energy rating 46.5ft-lbs, not max impact load, so how do I calculate it or come close to finding static load?

Lets say a tire compresses .25" from the impact (or .0208 ft or 1/48th of a foot), so static load is 46.5ft-lbs X 48 = 2232 lbs per blow?

Would the reaction on the chassis also be this load? or would it be less or more? If less, why is it less?

Is this the correct formula? I don't think i have enough know values to find the reaction load on the chassis, can anyone help?

Sorry for the long post.