Amaelle

- 309

- 54

- Homework Statement

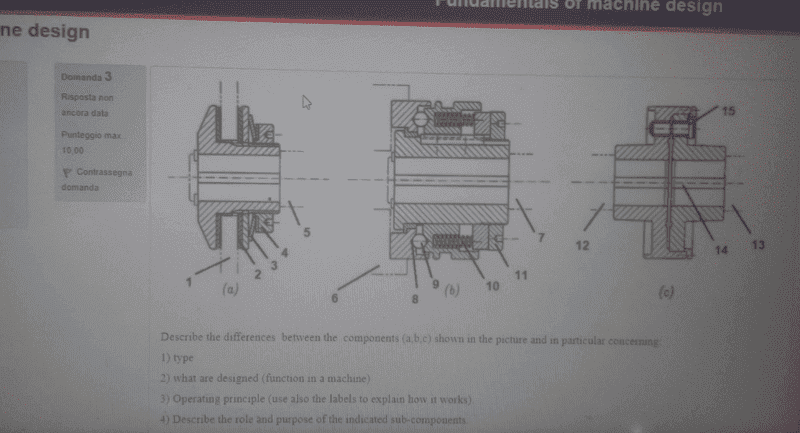

- Identify the elements of the safety clutches (look at the image)

- Relevant Equations

- safety clutches

Greetings

I need to identify the elements of the following safety cluches: we have three different clutches.

I lready identified most of them exept for number 14

Any help would be appreciated !

thank you!

1- output shaft

2-friction surface

3-preloaded spring

4-nut

5- input shaft

6- output shaft

7- input shaft

8-ogival seat

9-sphere

10-preloaded spring

11-nut

12-input shaft

13-output shaft

15-pin

I need to identify the elements of the following safety cluches: we have three different clutches.

I lready identified most of them exept for number 14

Any help would be appreciated !

thank you!

1- output shaft

2-friction surface

3-preloaded spring

4-nut

5- input shaft

6- output shaft

7- input shaft

8-ogival seat

9-sphere

10-preloaded spring

11-nut

12-input shaft

13-output shaft

15-pin