- #1

JJ91

- 41

- 0

Hello everyone,

I'm currently at third year of EPE and this software is totally new for me so i would to ask a few questions.

I have been asked to use infolytica MagNet using Field Sampler tool to analyse a flux behavior in the air-gaps and in the transformer core for 2 different core materials, 2 different coil materials and 5 different current ratings (2,4,6,8,10 amps).

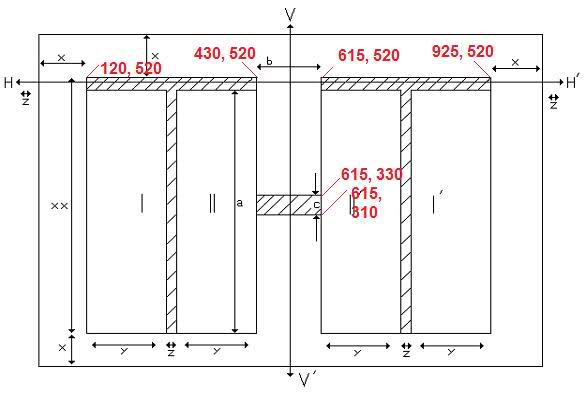

The design shows as follows:

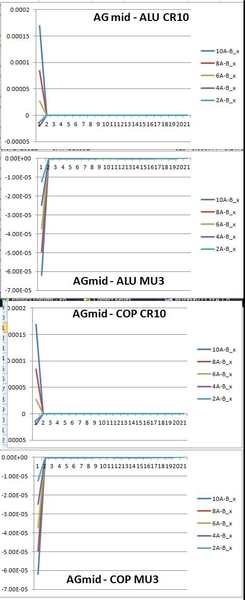

I've got most of my graphs and its now coming to write conclusion but there is 1 graph where I think something went wrong:

(the graphs represent the flux in the airgap or the 'c' point from the above diagram measured from TOP to bottom)

AGmid - Airgap in the middle of the core (between secondary winding)

ALU - aluminium (coil material)

COP - copper (coil material)

MU3 - Core material (lower than CR10)

CR10 - Core material (higher permeability than MU3)

http://www.2shared.com/file/WrczYYFS/Correct_Reults.html"

The air-gap in the middle of the transformer core and the B_x line is straight where I'm afraid it shouldn't be.

1. So I would to ask what went wrong and where should I look for mistake ?

2. Why there is a difference of direction between MU3 and CR10 from the above graphs ?

3. What else can I say from the graphs apart what is the strength, leakage, direction and magnitude of the flux in specific area ?

I'm asking here because report is due to in Monday,

Thanks a lot for any additional information

I'm currently at third year of EPE and this software is totally new for me so i would to ask a few questions.

I have been asked to use infolytica MagNet using Field Sampler tool to analyse a flux behavior in the air-gaps and in the transformer core for 2 different core materials, 2 different coil materials and 5 different current ratings (2,4,6,8,10 amps).

The design shows as follows:

I've got most of my graphs and its now coming to write conclusion but there is 1 graph where I think something went wrong:

(the graphs represent the flux in the airgap or the 'c' point from the above diagram measured from TOP to bottom)

AGmid - Airgap in the middle of the core (between secondary winding)

ALU - aluminium (coil material)

COP - copper (coil material)

MU3 - Core material (lower than CR10)

CR10 - Core material (higher permeability than MU3)

http://www.2shared.com/file/WrczYYFS/Correct_Reults.html"

The air-gap in the middle of the transformer core and the B_x line is straight where I'm afraid it shouldn't be.

1. So I would to ask what went wrong and where should I look for mistake ?

2. Why there is a difference of direction between MU3 and CR10 from the above graphs ?

3. What else can I say from the graphs apart what is the strength, leakage, direction and magnitude of the flux in specific area ?

I'm asking here because report is due to in Monday,

Thanks a lot for any additional information

Last edited by a moderator: