Manuel12

- 7

- 1

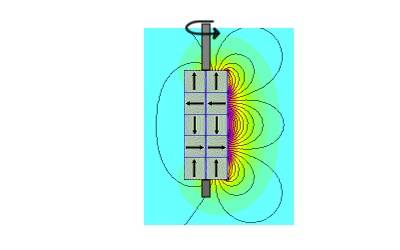

As a project, I am demonstrating electromagnetic induction by making an AC generator. The magnets I currently have access to are very strong neodymimium countersunk magnets, but I noticed that they utilise a Halbach array. I am aware that this means the magnet has alternating N-S poles spaced together, creating a stronger field on one side.

I assume the magnet and rotor would be something like the diagram below (there might be more "central" fields in mine)

Given this, can the magnets be used in a 2-phase AC generator? If yes, how would the surrounding coils have to be oriented?

I assume the magnet and rotor would be something like the diagram below (there might be more "central" fields in mine)

Given this, can the magnets be used in a 2-phase AC generator? If yes, how would the surrounding coils have to be oriented?