- #1

k.udhay

- 169

- 13

- TL;DR Summary

- How to consider the effect of spring in a mathematical model of a car with specific GVW?

I am in a process of making a mathematical model of an automobile driveline validation procedure called "Driveline impact". In this test, after the engine in cranked, first gear is selected. While clutch pedal is still pressed, engine rpm is raised unto its max. torque deliverable speed. In this condition, the clutch is snap released allowing an impact torque to pass through the driveline. In spite of the max. torque governing system, I understand a momentary higher torque will be transferred, as all such governing systems are responsive in nature.

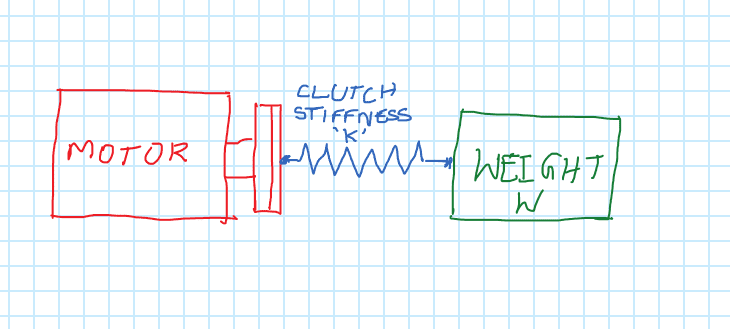

For the purpose of simplicity, I am thinking of considering only the three elements that majorly contribute:

1. The engine or motor that can produce any torque (ignoring effect of torque governing)

2. Clutch - To consider the effect of its stiffness

3. Vehicle with a GVW

Objective:

To plot the time vs. torque curve and therefore finding the max. torque point

Help required:

I have no clue as how to start. Especially I am unable to figure out to find the torque demand from vehicle. If someone can help me with a suitable derivation lecture available in the internet, that would mean a lot to me.

For the purpose of simplicity, I am thinking of considering only the three elements that majorly contribute:

1. The engine or motor that can produce any torque (ignoring effect of torque governing)

2. Clutch - To consider the effect of its stiffness

3. Vehicle with a GVW

Objective:

To plot the time vs. torque curve and therefore finding the max. torque point

Help required:

I have no clue as how to start. Especially I am unable to figure out to find the torque demand from vehicle. If someone can help me with a suitable derivation lecture available in the internet, that would mean a lot to me.