- #1

RobertGC

- 93

- 2

- TL;DR Summary

- Weight of water pipe.

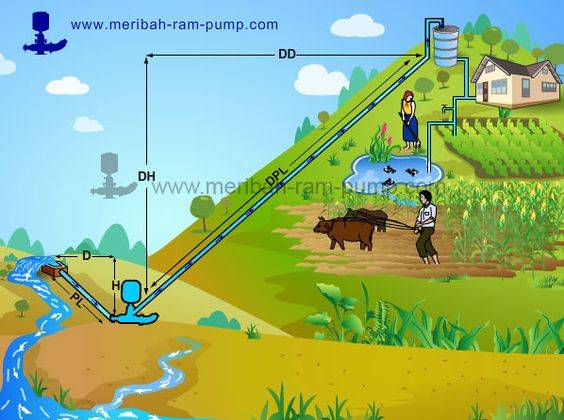

I’m trying to calculate the weight I have to support at one end of a pipe with flowing water. So suppose you had a water pipe that extended from the ground upwards some distance away both horizontally and vertically, i.e., at an angle. Normally, you don’t have to worry about this issue because the entire length of the pipe would be on the ground going uphill:

But I’m envisioning a scenario with it being supported at only the end point, aside from the beginning point resting on the ground. If the pipe is straight, empty with one end on the ground, at most you would have to support is 1/2 the weight of the pipe, when horizontal, with this supported weight gradually decreasing to 0 as the angle went to to 90 degrees, i.e., vertically upwards.

Now suppose you had static water in the pipe it would be the same idea with the weight of the water included. But it seems to me if the water is flowing then the pressure/speed of the water would naturally cause the water to flow upwards anyway so the weight that needed to be supported should be less.

But the curve the water would want to go on its own would actually be parabolic. So the curve you should actually make the pipe be in is actually parabolic instead of straight if what you want to do is minimize the necessary supported weight. Now this would make the length of the curved pipe longer so the weight of the pipe itself would be more than for the straight pipe. Still, assuming the amount of flowing water is such that the pipe is continually filled, no empty space, then this should still reduce the total weight by reducing the weight of the water needing to be supported.

But there is another complication. With the water contacting the walls of the pipe and the friction that thereby arises the speed and/or direction of the water is altered so it wouldn’t really be going *naturally* in a parabolic path on its own. So the weight of the water would still need to be supported to some extent even with the pipe is in a parabolic shape.

In that case what would be the optimal shape of the pipe to minimize this supported weight of the water pipe?

But I’m envisioning a scenario with it being supported at only the end point, aside from the beginning point resting on the ground. If the pipe is straight, empty with one end on the ground, at most you would have to support is 1/2 the weight of the pipe, when horizontal, with this supported weight gradually decreasing to 0 as the angle went to to 90 degrees, i.e., vertically upwards.

Now suppose you had static water in the pipe it would be the same idea with the weight of the water included. But it seems to me if the water is flowing then the pressure/speed of the water would naturally cause the water to flow upwards anyway so the weight that needed to be supported should be less.

But the curve the water would want to go on its own would actually be parabolic. So the curve you should actually make the pipe be in is actually parabolic instead of straight if what you want to do is minimize the necessary supported weight. Now this would make the length of the curved pipe longer so the weight of the pipe itself would be more than for the straight pipe. Still, assuming the amount of flowing water is such that the pipe is continually filled, no empty space, then this should still reduce the total weight by reducing the weight of the water needing to be supported.

But there is another complication. With the water contacting the walls of the pipe and the friction that thereby arises the speed and/or direction of the water is altered so it wouldn’t really be going *naturally* in a parabolic path on its own. So the weight of the water would still need to be supported to some extent even with the pipe is in a parabolic shape.

In that case what would be the optimal shape of the pipe to minimize this supported weight of the water pipe?